Got a Question?

Here is a paypal button for $10 Quote Consultation Fee. This covers my time in phone or email communication. Speaking writing and download/upload photos takes time. I charge for my time and services. This $10 does not apply to any parts or services and is non-refundable. I find that this tends to screen out 99% of emailers/callers. The 1% of emailers/callers are my buyers. I reserve customer service and technical answers to buyers only. I reserve the right to say no thankyou or to charge more due to the complexity of the question etc. I perform repairs and or diagnostics service for -circuit boards/parts etc. BUT no repairs and no diagnostics testing services are included in this $10 Quote Consultation fee.

Dr Virago Pete's Scanning Electron Microscope

International Scientific Instruments ( ISI )

ISI SX30 Scanning Electron Microscope ( SEM )

I am not affiliated with the ISI mfg in any way - other than I own one of their machines and seeking to restore it.

Here are the photos from my machine at the High School it came from.

I hope to find a source of used parts for this machine. I dont know yet what it needs. But as I delve into this machine - I hope that people-who-part-out-their-machine will contact me so I can get a quote on needed parts.

Here is the nicest comment about this microscope - which I found online

"Good resolution and image quality over wide operating voltage range (5 to 30 kV) •- 60 Å at 30 kV in high vacuum"

A Little Math Here:

1 Angstrom = .1 Nanometer

60 Angstroms = 6 Nanometer

Gold atom = 0.1441 nm radius (rounded)

Gold atom = 2.882 Angstroms approx size (rounded)

(There is alot of wrong/contradictory information online and in books so I dont actually know if the diameter of gold listed above is correct)

So, under ideal conditions (antivibration floor) one pixel on my screen will be 20+ atoms wide and 20+ atoms tall. I did place my machine directly over a steel girder I-beam just below the flooring - and the machine has built-in shock absorbers - I hope those two things will help the machine achieve its maximum magnification through stability.

Im estimating an approximate 150,000 x magnification maximum under ideal conditions (that was achieved by ISI installers a 70A guaranty - per the manual) Given that the monoschrome CRT screen size is only about 4" diagonal and the Polaroid camera print is about the same size.

60 Angstroms (6 Nanometer) is good for a microscope this size. The above may or may not be accurate as I found that review of this machine online (the ISI SX-30E manual which I have - says the mfg guaranteed min 70A at time of delivery/installation - that is astonishing considering how small this microscope actually is compared to much larger microscopes)

Parts Needed

1. Replacement parts for Secondary Electron Detector

2. Roughing pump

3. Manuals

4. I dont know what else

Parts I have

1. The SX30 machine and the column as pictured

2. Several 3 Ring Binders of notes and instructions (for ISI Super IIIa - a different model and very general)- all very thin and I may not have all literature - so if you have books and docs - let me know

3. A small cardboard box with parts and pieces and a few filaments

4. Secondary Emission Detector which was dangling when I picked up I marked it JN1 as it was connected to JN1 connector. I am working on restoring this sensor.

5. Alot of Steel panels (side front back etc covers - removed by previous owner)

My Notes on Parts Acquire Progress

1) Jan 2014 in discussion acquire digital image capture device which is DOS based possibly adaptable to ISI - I will need to locate schematics and port pinouts for ISI to adapt this board as it was originally intended for JEOL. Craigslist ad Wanted posted.

2. The seller has sent the circuit board and a CD-ROM for digital image capture (in transit at the time of this writing)

3. 1/12/14 the ISI SEM is indoors and off my trailer and out of the cold Chicago area winter where it was exposed to a record breaking minus 50 degrees F "Polar Artic Vortex" and then 2 days later the weather was 37degrees and slushy melting the 17 inches of snow. During this 90degree approx temperature difference (-50degF to +37degF) the SEM was moved indoors and is resting on a 1/2" plywood sheet to protect the floor from the extreme weight and allow rolling the machine to access the backside and all sides for rstoration work. It has been outdoors under a tarp for 5 weeks (Purch early Dec 2012). The extreme weight meant a ramp needed to be built and then dismantled and then the wood from the ramp re-used to make bridge over the doorway and then re-use the wood under the SEM to support its weight indefinitely. So it was quite a challenge geting it off the trailer and into its spot- A move of only 20ft away. It took 10 men and a Tracktorloader with forklift attachment and $100 worth of hardware store wood and steel hardware and a jetski/small boat trailer to accomplish this and payments to the labor provided. I didnt keep track of how many hours it took- but it was alot of hours on my part. I dont see any damage from being outdoors. Probably the deepfreeze weather prevented extreme damage from humidity because most days were very cold. Some days were beyond cold and are on the record books as the coldest days in history in Chicago area (I'm 35miles North of Chicago). There are some tarnished areas where I saw this at the time of purchase. This machine was outdoors in its previous life, and I saved it from a landfill fate. I couldnt save the carbon coater from that fate because it was just too heavy and big. It probably weighs as much as my SEM. I have included a photo of it here as a download - I dont own this carbon coater but I was offered it for a mere $100 and includes a pump. I just dont the room for it and my small space cant support the additional heavy weight machine.

I am including photos of the Edwards Sputterer which was offered to me by th esame seller. I have no way to transport it - It was a true bargain for $100 but I had to pass on it. I think it is for carbon sputtering as my best guess. This Edwards sputterer was the mating set for my ISI SX30 microscope and I was told the sputterer contains the roughing pump. I will need to acquire a small slow roughing pump to fit my small space. I purchased my SEM from a High School 40 miles south of my location.

Update 1/12/14 regarding Edwards Sputterer

I contacted the seller to say thanks for the SEM and to let him know I would pass on the huge Edwards Sputterer and he replied that the sputterer was sold last week and the buyer "hauled it away" and believe me - I'm sure it wasn't easy to do because it is one big heavy machine. They probably used the same big yellow tractor loader with forklift attachment - the same one used to load my SEM on to my trailer. So the downloadable pictures of the Edwards sputterer are only for FYI as I did not buy it - but it is part of the history of my SEM.

|

Edwards Sputterer.zip Size : 522.617 Kb Type : zip |

Here is an email I sent to the seller of a image capture device called "Image Thief"

The seller said that it was removed from the SEM because it stopped working and they replaced it with some other device - it was originally in a Jeol SEM 5600 but I hope to adapt it to ISI SX30 if possible. The first step is to purchase it (done) and troubleshoot the boards (done) and this is what I found as postential issues:

I did some testing on your Image Thief Board and the DMA card and I see 2 possible reasons why you had an issue a decade ago.

None of those are a complaint- I'm happy as a clam to have this item so dont get me wrong.

I'm just sending this as an FYI because maybe you were wondering what happened a decade ago and why it stopped working.

I

tested the Image Thief and there were 2 chips I didnt have a tester for

but everything else tested fine and was nice and socketed.

I

tested the DMA board and found one chip which gave me a fail only once

and I couldnt get it repeat that- subsequent tests always passed. So I

may attribute that to operator error (me) or possibly an intermittant

glitch inside the chip. Regardless I wrote a note and will save that

information and that note will ride along with the card in its plastic

wrapper for future reference.

Another thing I saw was several

bent pins on the backside - I tested it on an esr capacitor meter and

all the capcitors one by one tested fine. There wasnt any chips which my

collection of testers skipped over on this board. So all socketed chips

tested fine. There are a few soldered in chips which I didint test.

I

usually stop troubleshooting at the very first sighting of a potential

problem and I think this one is big enough to have caused a malfunction.

See

there is a group of pins sticking out on the solder-side of the board.

For some reason someone at the factory was half-asleep and put in a

capacitor only halfway. Then they soldered it in place much much taller

than the other capacitors on the same board. Now functionally - this is

not an issue. However the board came into contact with something of

great force - enough to bend the pins- that takes alot of force to do

that.

The 3 pins are bent over in such a way as to make me think

at least one was possibly touching each other or the U14 chip next to it

- or possibly up against some metal object.

I sent some photos

here and you see the bent pins - I'll straghten them and also desolder

the U14 chip and probably some more chips for testing purposes - but

most likely none of those chips are bad- it is all low volts 5v or

possible was shorted to ground - either way I dont expect to find any

chip errors.

That may answer some questions about why it stopped working 10 years ago for you.

My

photos are not super great but you can clearly see bent over pins and

those pins are from the too-long capacitor which someone didnt trim off

the extra length of legs at the factory.

Here are some photos of the DMA 8-bit board- it shows the pins bent and it is very likely to have been the issue while installed in the Jeol 5600 SEM. I will straighten the pins. The IC chips and capacitors I tested them on my equipmnent and they look fine. WIth the exception of 1 intermittant chip and that may have been my error but nevertheless - for good measure and just to be sure the device is rock solid 100% I will plan on changing out that IC Chip. When checking ICs it is important to notice and pay attention to odd things and those could be trouble spots. I'm lucky I saw it fail one time and I never could get it to repeat. I'm lucky to have seen that. Luck has very little to do with it really - I've seen that sort of thing before. It is a good idea to change out the part.

|

DMA board bent pins.zip Size : 4410.188 Kb Type : zip |

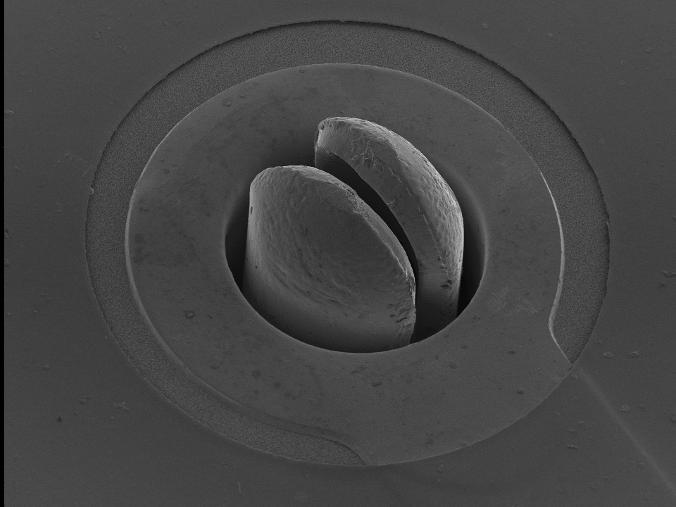

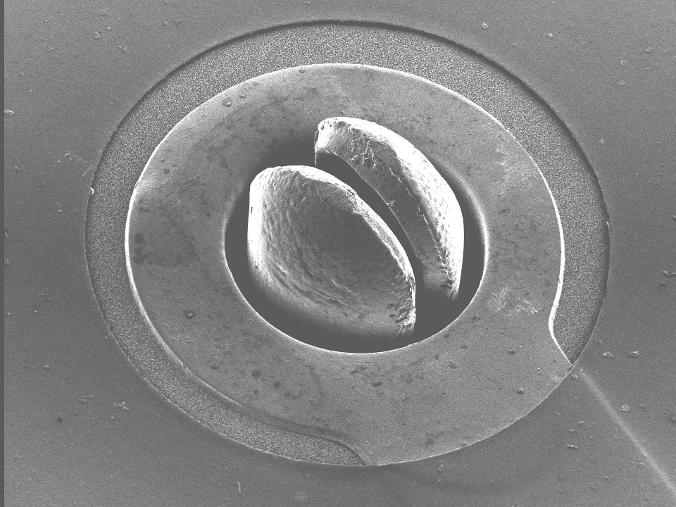

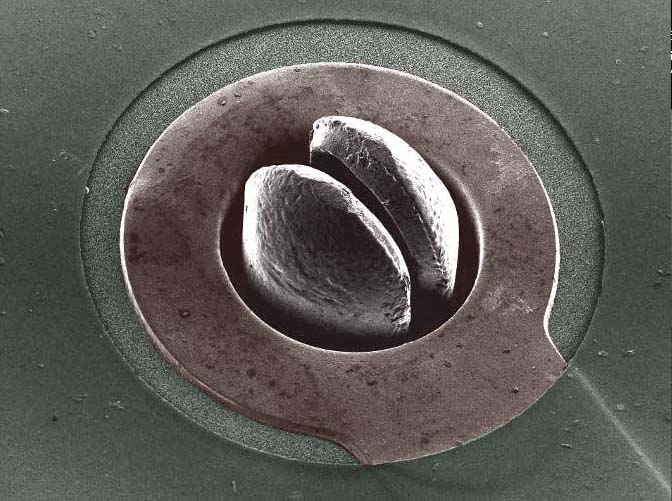

Above pictured "Image Thief" homemade perfboard prototype digital capture board and cable and DMA 8-bit card and manual. This board was used to capture a very wonderful SEM photo on a Joel 5600. I have included here an actual photo that this very board captured ten years ago on a totally different microscope - attached to a DOS Pentium 133 PC. I hope to be able to connect this board to my ISI SX30 and achieve similar photos. I need port and pinouts and schematics to be able to do that. Anyone have schematics or port pinouts for ISI SX30? Here is the wonderful digitally captured photo. It is astonishingly sharp and clear. Wow.

Here is a link to the authors and inventors page - he is working on a USB version and is an open source project. I asked to purchase his old non-working board. I believe it will now work as I tested most chips and found bent pins and straightened bent pins and cut them short/close to board as should be.

It looks like the monstrous cave worm the Millenium Falcon flew into in the asteroid field. But seriously it is not a photo taken by me. The inventor of the "Image Thief "captured this image and is a PCboard trace and island with a component in the hole.

Here is a link to the inventors page and open source project

http://people.umass.edu/~dac/projects/ImageThief/ImageThief.html

I have a penpal and he said about 15 yuears ago or so he built the Imgae tHief and installed it on a Joel 5400 and it worked very well. He said teverything I needed to build it and the softeare and everything was in the downloadables. He made his own board from this download.

I asked the author if he could could sell me a prebuilt one and I jumped at the opprotunity to buy the actual board that made this picture The image measures approx 2000x1400 resolution and is very detailed. The inventor wants help on his open source project and I am not a programmer in assembly language or USB familiarity - but I am good at sourcing parts and people. Maybe a reader will see themselves as helping in the progress of the USB version of the "Image Thief" open source progress.

I myself am going to do my best to get the older DOS version up and running. My microscope is from that same era. Mating my vintage ISI SX30 with a vintage DOS PC is what I intend to do. I suspect this photo was created by using a backscatter detector whereas I will be using a Secondary Emissions Detector so The image iteself will have different highlighting method/appearance.

Another important point about the Image Thief is - I dont see the data infomation such as KV or magnification on the image itself. It leaves the image clean and uncluttered and unobstructed. It is a beautiful image. I hope to someday make an image of this quality myself using SED and in a different subject matter - but nonetheless very comparable quality-wise.

|

pcb_full.jpg Size : 266.013 Kb Type : jpg |

I carefully stored the sensor which the seller said to be careful with - but I found that it actually had been mishandled very badly before I ever saw the machine. The sensor was broken off and because I had never seen an electron microscope upclose or in-person I just assumed that the sensor is supposed to be on the table and connected when you plan on using it- because it was not connected at the school. Its funny that someone told me to be careful with it - when obviously it had been smashed separate from the column and probably dropped on the floor. The telltale sign for me that something was not right was a tiny rattling sound .

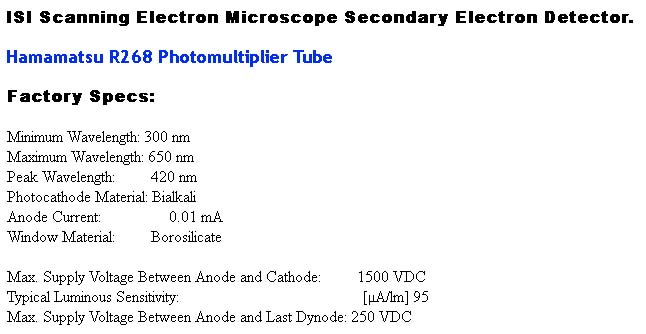

I unscrewed it expecting to find a loose screw and save myself from an electrical short. But it wasnt like that at all. What I found was a tiny piece of glass and this piece of glass was the"belly button" when a tube is blown and sealed by the glassblower or machine. So I knew that the photo multiplier was bad before I disassembled too much. As I disassembled more I saw a large crack and a white cloud ring inside the tube and all of the pins were crooked and bent in all directions. (Is it possibole someone tried to unscrew a vacuum tube as if it was a lightbulb - yikes) Here are some photos, and I need to start looking for a Hamamatsu R268 Photomultiplier Tube as mine is broken from the previous owner bumping into the sensor and it dropping on the floor most likely (or possibly sabotage) I will need to make a replacement plastic mount on my lathe but that is not my big concern - finding the tube is probably one thing that caused my SEM to almost get scrapped. I see an ebay tube with Make Offer and I may try to make an offer on it. I see one sold for $40 back in March of 2012 when I do a google search but I may not get so lucky to find one at that price. Maybe the reader has one they can sell me?

Here are some photos of my disassembled sensor - there is really not much to it at all. I will store it in a plastic mayonnais/salad dressing type jar for safety as the glass shards can be dangerous to my pets. A thorough vacuum with a shopvac for fine glass fragments was also done in the entire area.

Some possible cross reference to this tube made by Hamamatsu - Philips, EMI, Burle, and possibly other brands. If the reader knows of a possible substitute let me know as that will widen my search and make it easier to find a replacement - if there are substitutes from a different mfg.

Some online vendors scavenge old lab machines and find tubes or have an inventory of used or new tubes. I hope to find a replacement for it.

The location / placement of this sensor on the SEM column makes it easy to brush against it if the machine is put in high traffic area where people can brush up against it.

The sensor is basically a light sensor - a very sensitive one. I have 3 photomultiplier tubes in my Kodak Telecine made in 1973 (one for red blue green) but is otherwise solid state. I have read that photomultiplier tubes are extremely sensitive and that is why it is a vacuum tube rather than solid state. The other many PCB circuit boards are solid state with many IC chips and transistors. Having one tube inside of a solid state machine seems a little out of place - but the simplicity of the sensor is astounding that it comprised of a photomultiplier tube and a litle round circuit board with one chip - inside the sensor housing.

I dont know enough about the microscope at this point to give the sensor a name - possibly "secondary electron SE detector"? It is basically a photomultiplier tube facing a glass window (short fiber optic glass) facing the specimen holder. As the electron beam strikes the specimen it creates light and the photomultiplier detects it. What wavelength of light - I dont know yet - probably not visible light.

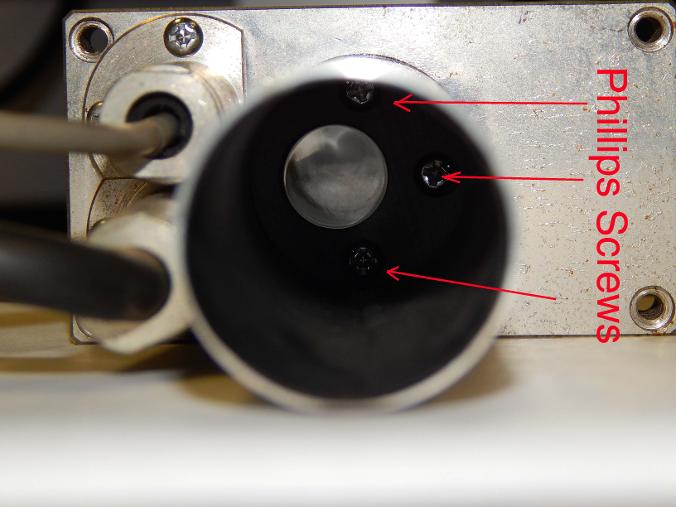

Shows broken off metal can housing from Secondary Electron sensor. See the black plastic round piece that was once part of the mount. When I first got the SEM I thought it was a round gasket - but no it is part of the plastic mount. This is the way I bought it. No damage was done by me. I either need to find this round plastic piece as a replacement part or fabricate it myself or epoxy it back together and stregthen it. It is most likely an electrical insulator - I cant image that the factory arbitrarily decided to make it from plastic when almost the etire machine is metal. So I would imaging it is an insulator. As a replacement a phenolic or glass-filled high temp plastic would work. Since this plastic piece is right next to the hot PMT tube - it needs to withstand heat. The edges of the round aluminum tube are crikled like like someone tried to straighten it. There are ridge rings inside of the aluminum tube where the round plastic piece is. This means it gets pressed in place and the ridges keep it there. The plastic round black piece isnt intended to come out as once it is pressed in there the ridges lock it in place. Maybe there is enough ridges left for me to apply some epoxy and then try to repress the aluminum tube over the repaired plastic.

The boogered up end of the aluminum tube makes me thing that I need a tube expander to do a good job to straighten the tube end which is crinkled and attempted straighten by the previous owner.. I purchased a muffler/tailpipe expander last year and it may contain a mandrel of the right size. I'll have to ckeck on that.

You would thunk that there would be some kind of guard surrounding these sensors sticking out th eside of the column since they are so delicate and someone bumping in to them is a real possibility. I will consider welding on some type of barrier between my room entryway door and the SEM as I dont want this to happen to me years down the road after I had already fixed it.

See the socket for the photomultilpier tube

Hamamatsu R268 Photo Multiplier Tube which I need to find a replacement as it is cracked. Pins are bent in all directions - when this was broken it probably made a big crashing sound and a loud pop when the glass broke. I hope I can find a replacement tube. I can fix the mount and the metal housing.

Photomultiplier tube is sometimes written Photo Multiplier Tube or PMT for shorthand.

I was communicating with a scavenged parts supplier for SEM microscopes and I ordered a replacement used tube which has the black round plastic piece and an ISI SX30 200page approx Service manual. I am happy with the price negotiated for these 2 items. Here is a picture of this aluminum tube (I have not received it as I am writing because it was just ordered today 1/23/14. This seller also had a glass vacuum tube R268 Photomultipier tube but the price was beyond what I can afford. I will need to search for another source for this. I have maxed my budget for while.

I will need to figure out a way to protect this aluminum tube from being leaned on or brushed against as I may not be so fortunate to find another one in the future. I may need to weld a brace onto the frame so that a protective shield encases this delicate perpendicular sensor which is resting on a very thin plastic plate held by 3 philips screws. It would not take much to shear it off. I can imagine the gut wrneching feeling that would have been for someone to have destroyed an SEM microscope with an elbow or a backpack brushing against it (possibly - who know what really happened).

I saw a very rusty ISI SEM column on an auction site

I read that SEM columns are made of stainless steel - the author was not correct. Columns are made of steel with a decorative plating. The frame is steel. The control panel is steel. The electronic enclosures are steel. Lots of steel. Very little plastic. I dont see any stainless steel- maybe there is a piece somewhere made of stainless steel - but the column is not stainless steel. The author of that article was wrong about the column being made of stainless steel. I saw a very rusty column on big-auction-site which the plating was being pushed up all over due to the underneath rusting of the steel column. The fact that it was so rusty - tells me it was steel and was outside in a boneyard for a long time.

Also is visible the thin black rubber gasket which goes behind the round plastic piece. The gasket came with my replacement parts. I'm glad to have purchased these parts.

I ordered and received 1/2014 the replacement aluminum tube and also the black round plastic piece (from scavenged parts supplier) which goes on the end of the tube. The plastic piece is a mount for the tube to be attached perpendicular to the column. These parts are from the Secondary Emisssions Detector. I am glad to have these parts to replace my broken plastic. In addition I purchased a technical manual (from scavenged partts supplier) for ISI SX30 which shows adjustments for voltages and pictures of waveforms. This 200page 3-ring binder book jumps right into the adjustments and calibration but I feel there is proabbly some other book which I'm missing still.

I dont have schematics or an overall layout of which parts and pieces should be in this ISI SX30 microscope. I dont have a port diagram or pinouts showing me the data for each port- which is really what I was asking for but still this book is a great help to me and I will be able to check voltages at the power supplies etc. But I will continue to look for more books - maybe a reader has a book they can sell me?

I see a couple of things not attached to anything and I'm scratching my head on whether something should go there or not.

I plan on making a video showing the ISI SX30 with the panels off and pointing out the parts that I need clarification - maybe that will help to identify what needs to be purchased for it.

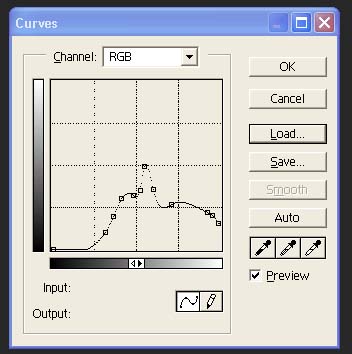

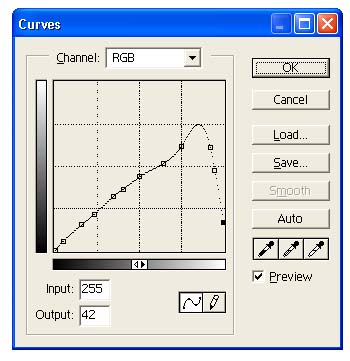

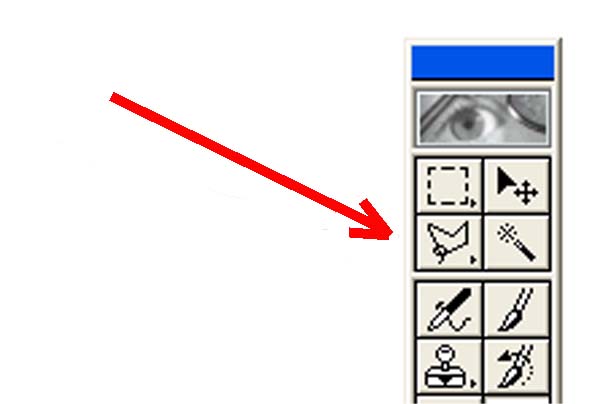

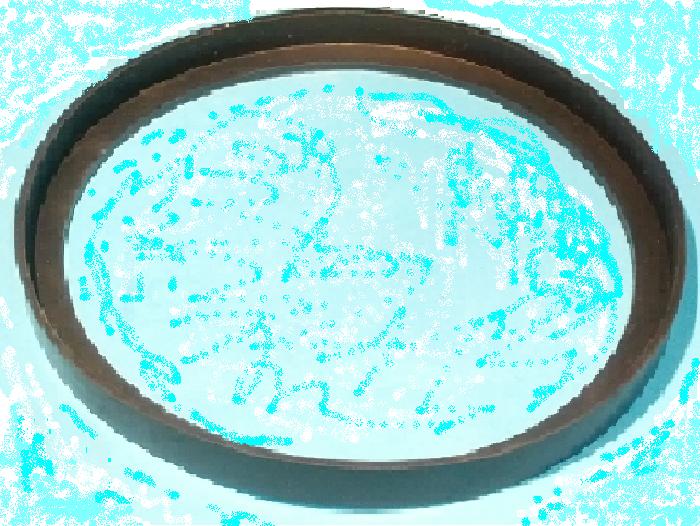

I always liked how Secondary Emissions images looked like as they have a surreal metallic looking appearance. Where Backscattered images look like light-photographs and closely resemble how our eye sees. Secondary Emissions created photos have a SCI-FI look that is hard to describe -except that there is a white outline which sharpens images and sometimes shadows are white rather than black. It almost looks like a combination of a positive photo and a negative image all rolled-up into the same image. I played with Photoshop 5.0 to duplicate this SEM Look of Secondary Electron Images or to correct it to look more like Backscattered images and what I found is that if I go into "Image/Adjust/Curves"

I find that images which are created on a Secondary Emissions Detector can be made to look more like Backscattered created images by using the above curves (I invented this process (C) Copyright2014 All Rights Reserved) and I believe that it is due to the clipping or attributes of the image sensor. The above curves reverse the trend for shadows to be white- they should be black to look more like our eyes see. Instead the sensor at a certain point starts to display shadows as shades of white. The above curves reverses that. Now depending on the SEM the curves are in different points on the graph but the idea is to find the point where that SEM starts that white shadowing and then make the curve sharp in that spot - this "fixing that image" to look more like a backscattered image.

I actually like how Secondary Emissions Imags look - so dont ge me wroing when I say "fixing image" as the surreal look is quite amazing and I like it alot. Because I understand graphics - I recognized this as a function of the curves within Photoshop 5.0 and later versions have this too. I sometimes began with a photonegative of the image or a positive of the image - it possible to work these curves from either positive or negative. Easy to flip positive/negative in photoshop by "Image/Adjust/Invert" also since SEM images are grayscale making the image grayscal helps "Image/Mode/Grayscale"

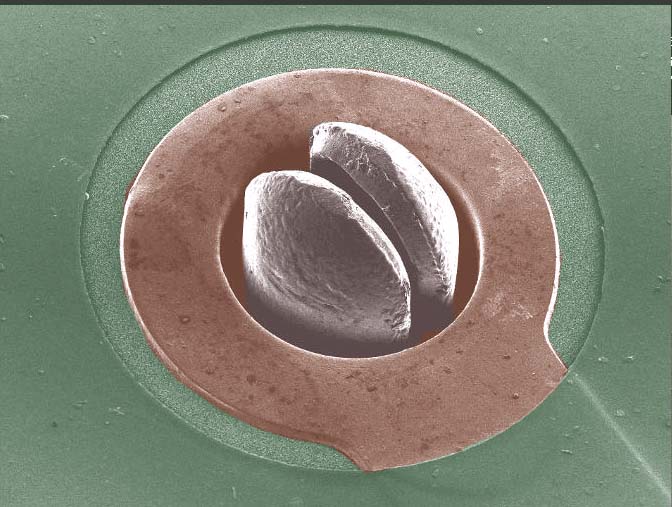

The above image was redone in Photoshop to create a fake pseudo Secondary Emissions detector image - made from a Backscattered detector created image. I used the above curve to create it and then brightness and contrast to give it the correct overall correct tonal quality for viewabilty. See how the details now stand out so much more pronounced. It is my hunch that the SED and Backscattered detectors have different curves and this is transposeable between images produced from SEMs with Backscattered or Secondary Detector created images. I see very little reason to have both detectors on my machine. I think my Secondary Emissions Detector will be just fine for my needs. Once I have it working - that is. Choosing between Secondary ELectron Images and Backscattered images sometimes has to do with the depth or flatness of the subject being scanned. I think this technique blurs the need for choosing which detector to scan the image with.

It seems to me that some authors writing about SEMs and how they work are incorrect in their understanding of the materials the SEM colums are made of and also in their understanding of Photomultiplier tubes and those authors feel that something different is being resulted in their image- whereas I feel that much of this is simply curves in how the photomultiplier tube sees. It is not a straight line. There are less sensitive/insensitive/overly sensitive areas of the curve. These can be corrected or exaggerated or turned opposite by using the curve.

The same TIF file produced both images - it is just a different way of displaying the same scanned data. The data itself is the same or similar as long as you realize the Photomultiplier tube itself is slanting the data or skewing it.

The above colorized image was created in Photoshop 5.0 by selecting (lassoing) the area to be colored and then Image/Adjust/Color Balance and using the sliders to color only the selected area. Then selecting or lassoing another area and coloriung that portion of the image in a different color. The colorization gives the image a pastel-like look that is very typical of colorized old films. The colorization is non-destructive as merely using the Photoshoop "Desaturate" function removes the colorization and restores the original B&W shades of grey/gray - however you spell it. This process can be used to highlight key areas of the image or to give the image the proper colors - as if we were viewing the object in sunlight rather than B&W color-less electrons.

In the above example - it shows a green circuitboard with a copper trace and a shiny silver-color component sticking out the through-hole. The colorization of the copper-color and green circuit board make it more realistic - but still gives it that surreal SEM microscope look - which I like alot. So we took a SEM Backscattered Detector image and from that created a colorized fake SEM Secondary Emissions Detector created image.

Comparing the before and after results is quite remarkable, and the image is much clearer and easier to view and understand. It is important to note/mention that the image was modified in Photoshop so the viewer knows. Photoshop is often used - without anyone mentioning - that it was used. Showing both the original and the Photoshopped image can go a long way to satisfy those that need enhanced images and those that like original unmodified images. Providing both - is always a good idea and adds to the credibility of the image rather than detracting from it.

I should also point out that Photoshop 5.0 also has the ability to adjust the saturation level. The colorized pastel-look can be made milder or more exaggerated by using the Image/Adjust/Hue Saturation slider left-or-right. Also brightness and contrast and other functions help bringout details in the image.

I would like to find a new or used 14-pin Photomultipler tube

(Any of the following would work)

A. Hamamatsu R268

B. Burle S83068E (Exact substitute for R268)

C. Hamamatsu R6095 (recommended by an online website vendor as a replacement but wrote not quite as rugged as the original R268 - whatever that means. That website said that Hamamatsu discontinued the R268 and the mfg recommends R6095 as the replacement - I dont know if that is correct. Can someone confirm or refute that?)

D. Various brands 9524B

E. Various brands 9924B (different number of dynodes than R268)

F. Thats is all I can find - if you know of another substitute - let me know

Update 2/3/14 I received an anonymous response to my Craigslist ad looking for ISI SEM parts and the message said, "Fyi, I believe that a Thorn EMI Model# 9924A will substitute for the r-268 that you need." I dont know the sender and I cannot verify if this is a fact or a hunch on the sender's parts - can anyone confirm or refute this?

|

Burle S83068E direct replce for R268 Data sheet.pdf Size : 349.037 Kb Type : pdf |

2/23/2014

I am putting forth effort to buy 2 things - a Hamamatsu R268 used PMT tube from an ISI SMS2 and a flip open cover from an ISI SS40 (slightly too long but I am hoping to modify it to work). This week was dismal for me saleswise as the cold winter weather (An extra few weeks of winter and extreme cold conditions - Polar Artic Vortex) probably depleted most people of their paycheck as utility bills were astronomical (Mine too). Also the Olympic Winter games and Superbowl drew large viewing television audiences (watching TV reduced online browsing) and having all three events all in the same short period of time - affected my online sales. I am hoping that the end of the month will bring in some needed sales - so I can make these 2 purchases. These 2 vendors of used ISI parts have been very kind in granting me a small grace period - and they wont hold out forever so I hope I wont miss this opportunity to obtain these 2 parts.

Ironically I'm fixing a formerly half-million dollar machine and having trouble coming up with a few bucks to buy scavenged parts. LOL.

The wood to build the ramp costed more than the microscope purchase price. Aint that something. And these small replacement parts cost more than the wood. But I'm not complaining. Ill find a way.

The above picture shows the used Hamamatsu R268 tube and detector I purchased.

2/28/14

I received the Hamamatsu R268 tube (which was part of a detector) which I purchased on big-auction-site for $100 plus shipping. This detector is from a SEM microscope being parted out by the seller. The other parts I saw for sale from that seller - were very very rusty and I'm so glad that the pins of the tube are not rusty at all. The tube and tube socket are nice and clean and the tube was not rusted in place or anything. The tube looks nice and clean and the only flaw I see visually is that there is a circular scratch on the sensor end of the tube- probably caused by someone breaking off the detector from the very same plastic disc. The very same black plastic disc was broken and the previous owner was fortunate that the tube didnt get cracked. At this time I feel that I have a potentially working PMT Photomultiplier tube. I am also thinking that the circular scratch that I see may or may not be a scratch. I'm wondering if it is a calcium or lime ring or other chemical ring. I dont know at this point if it is a scatch or not. But the sensor should be able to see enough to function as the scratch is not a visual obstruction and the tube's vacuum doesnt seem to be compromised. I can tell that the tube is still holding a vacuum by the "getter" inside the tube. This getter is a chemical they put inside the tube as they are sealing the glass during the mfg process. The "getter" absorbs whatever remains of the air inside and becomes chemically bonded to the "getter" If air was introduced by cracking the tube - the "getter" would change color to white. So I know that there is no crack in the tube glass. Whether the tube is good or not remains to be seen - but I know it is holding a vacuum and visually looks good-enough.

My intention for the above 2ea photos was to show the circular scratch on the used tube I bought. The circular scratch is minor and didnt show up well no matter how many times I tried with various lighting conditions. But interestingly if I turned the camera flash on or off - that made a big difference in the translucent qualities of the sensor end of the tube. A Camera flash makes the sensor end transparent. No camera flash makes the end of the tube opaque. I am likening this effect to LCD shutter glasses or auto-darkening welding helmet (except opposite - a welding helment darkens when it sees a flash). The inside of the tube end is coated with a coating. My cracked tube does not look like this and my cracked tube has the silver side very deteriorated from within. The inrush of air had a very violent effect on the broken tube? Who knows - I am only guessing.

The above 2 pictures show the column liner which is made of brass. It is made of many small sections which are threaded (like how a ball point pen is disassembled) and each section contains a small insert with a tiny hole. My question is about the odd looking section above which is actually "floppy" and dangles. It reminds me of a pen assembled without the metal ring in the center. Can anyone confirm that the section shown in the above pictures is supposed to be like this? Or is something missing? I would like to buy a spare Column Liner (like pictured) if someone has one for sale.

Update 3/5/14 I received a reply from a knowledgeable vendor of ISI parts that my Column Liner is supposed to look like this. The "gap" is normal and looks like this. So I am relieved that I am not missing a piece. I am still looking for a spare column liner and more parts and books.

Update 6/11/14 I received an email from a university student looking for information on the ISI microscopes. I'm restoring this SX30 machine and acquiring parts - but I've actually never operated one or seen an SEM in person - only my own machine. My skills in repairing electronics are general so I have no doubt that I will get this machine up and running. My budget is limited so it will take quite some time to complete this machine. I still have to buy a pump (and step-down transformer) which I believe the original pump was a "Hitachi 160VP CuteVac" which is a 100 volt pump. I see other ISI Electron microscopes of various models on websites and big-auction-site which are using the Hitachi pump - so I am fairly sure that is what the machines came with - although the manuals dont mention which model it came with originally. My machine didnt come with a vacuum pump. The seller of my SEM offered a BIG BIG BIG and heavy carbon coater machine with a bult-in pump for $100 but I had to pass due to the size and weight - due to floor space and extreme weight would damage my floor (someone else bought it a short time after). My SEM was so big and heavy that it sat on my trailer for a month until I could figure out how to bring it off my trailer and into my small lab and build a ramp and pay people to help me. So that was the best I could do- especially just a couple weeks before "Polar Arctic Vortex" storm hit my area - coldest winter (-50deg F) in recorded Chicago area weather history - dating back - records kept even in the 1800s. I couldnt have done any better or worked any faster with limited resources. Even now as I write in June - its been 2-1/2 months since I purchased any parts - I'm still paying off my winter bills in installments and being hounded by utility company. $1500 utility bills for one month is hard to tackle when you have regular months bills to pay too- yikes. Even so I am juggling 3ea restorations at the same time Thermojet 3d wax printer (see my webpage for restoration) Rank Cintel restoration (see my webpage for restoration) and ISI SX30 Electron Microscope Restoration (you're reading it right now) I saw an ad for an SX30 being sold online by a SEM microscope reseller- the price was $30,000 and in working perfect condition. I could never afford that. I'm glad to have a fixer upper and worth all of the effort, expense, time it takes to restore it.

I noticed that Windows XP running Firefox 12 and Flashplayer 9 does not work anymore for the webhost I use - for uploading photos. I was going to upload a photo of the Hitachi 160VP vacuum pump but I am forced to upgrade software. Dont you hate that? I purchased Windows Vista 2 weeks ago ($10 approx from big-auction-site and came with a memorystick 128MB) and will need to buy an IDE hard drive (I learned a long time ago to install a removeble HDD for each version of Windows so I can just swap back and forth between OS by just exchanging the HDD cartridge) and install that sometime. One step forward and 2 steps back ... Once I have Vista up and running (have to buy a HDD first) - then I think the later version flashplayer downloads will load fine. But text functions work fine. This webhost doesnt offer ftp (old school way of uploading files) and relies on manually upload my files as I build my webpages manually as I go.

Update 6/18/14 I see that my website host has fixed the upload issue which has plagued the hostsite for months. Today it worked very well; And so, I uploaded a photo above - which shows the nameplate of the Hitachi Vacuum Pump which I suspect is the original model. I could be mistaken; But, it my hunch that it is what the SEM came with. I don't yet have a vacuum pump.

Update 7/29/14 A phone call from ISI SX-30 owner confirms that his microscope purchased 1 year ago came with the Hitachi CuteVac 160VP and he said there is no voltage input sticker on his unit - so the input voltage of this pump is not known. I believe it is a 100V pump and requires a step down transformer to operate in USA or overheating or premature failure is a possibility. It is not clear whether the transformer is intended to power the pump and SEM microscope simultaneously.

I am still looking for an ISI Transformer (beige rectangle metal box weighs 75lbs approx) -

Let me know if you have one for sale.

Update 7/29/14 I have added this photo after having a conversation by telephone with a 1year owner of a ISI SX-30 and hoping that an exchange of information will take place that is mutually beneficial (he has more manuals and has a more complete system than mine at the present time) the callers concern was that he does not have the correct input voltage to run his machine. The above picture is one in which I show how the transformer is sett-able to various input voltages. Also by using the -10V or Zero or +10V or +20V you have fine tune the input of either 100V or 140V. I dont have a transformer and have never tried this so this is my professional "hunch" and it makes sense that it would work - but I have never tried it. I have been looking for a transformer and found one on ebay but price is out of reach - so soon after Polar Artic Vortex record breaking winter and I am still paying off my utility bills - so this big-auction-site transfomer is out of reach financially right now. I asked the caller if his transformer has a cover over these wires and terminals and he said that there are 4 screws on a cover plate which needs to be removed to expose this settable terminal area for various input voltages. Please note that the ISI SX30 microscope runs on 100Volts AC. Do not attempt to run it on household power which is at least 20+ volts too high. You must use a transformer. I feel that setting the transformer to 130Volts AC input and output of 100V is "close enough" to work properly. I also noticed that my household outlets provide somewhere between 123v and 126.5 volts depending on time of day and seasonal use. This recent voltage climb in my ac outlets is due to a change in USA power and is common throughout the USA. Some areas of USA are still running at 115volts or 117volts (my area was 117V until a few months ago when a electrical transformer tower construction / road construction commenced). My area was one of the last areas to change. This 126.5Volts AC coming out of my outlet means that many of my appliances and technical gear is receiving too much power and a step down transformer is a must (such as a Variac). I hope that the caller will help me by providing a photocopy of the manual and schematics. He tells me that he has a complete schematic diagram of the entire SX-30 in his manual and is on several fold-out "centerfold" pages. I hope that I can acquire those badly needed schematics.

A third input voltage option - not pictured (I created this photo using PAINT software 7/29/14)

There is also a +20 volt terminal so that gives a third input voltage option which is 100V plus 20volts = 120Volts which would also be "close enough" but since the actual voltage fluctuation in my AC outlets can go to as much as 126.5 volts - I think having it set to 130V input is better - but that is just my hunch. It is best to take a reading with an accurate multimeter and see what the transformer actually provides at each setting. The real world and book-learning are not always the same. Thats where a voltage meter would come in handy and what I recommend for the reader - take a reading of your transformer before actually hooking it up to your microscope. If you blow your microscope it is your fault not mine. Setting it incorrectly is a matter of your own voltage in your area as power throughout the USA is not standardized- and they change it without notifying you. Imagine that! The SX-30E manual states that the microscope requires 1700watts - it is not clear whether that is with or without the vacuum pump running - no mention of which pump etc in found in the manual. The caller has the SX-30 original manual so that would help alot to have the correct manual rather than one that is a fairly close model.

Please note that a Variac Variable ac transformer is also an option where the output voltage is infinitely adjustable and is a more precise way of obtaining the correct output power. But the high amperage and wattage of the microscope and pump means that the transformer needs to be heavy duty. I like the ISI transformer as it is beefy and robust. The only disadvantage is the "close enough" voltages that are selectable in only 10v increments - versus the Variac where it can be set precisely to the correct voltage. Of course - dont accidently set the Variacs knob too high or too low or "magic smoke" will be released from your microscope electronics and will cause your SEM to die. I like the transformer and I want to buy it - but I dont have the funds right now. If it is purchased before I acquire the funds - I may have to go with a Variac as they are common to find on big-auction-site new and used in the 2000watt or 3000watt range.

I have created the above drawing which shows the terminals for ISI step down transformer included with many models of 1980s SEM microscopes. Note that having an input of 100V and an output of 100V makes absolutely NO Sense and this transformer does not accept it.

WE ARE SETTING THE INPUT VOLTAGE NOT THE OUTPUT VOLTAGE THE 100V OUTPUT IS A GIVEN

When they should instead set to (for example) 100V +20 OR 140V -10V

I HAVE DONE MY BEST TO EXPLAIN THIS - DONT THROW IT OUT. DONT WASTE THE ISI SEM OR TRANSFORMER.

Also, I have noticed that the printed numbers such as 100V and -10V may not be accurate - so always check the output using a multimeter before actually powering on your SEM. (for example providing 119V actual input setting the transformer to 90V - gives an output of 107V but in theory should stepping up not down- see what I mean) So there is a bit of trial and error in getting the settings right (but not while connected to SEM)

I suspect that when I actually receive a transformer, if I create a real-world matrix with input voltages versus output voltages - then there would be some variations. Such is the difference between "classroom learning" and hands-on experience and even so I am without any manual in this transformer settings.

|

ISI Transformer Matrix Full Opposite Alternative.JPG Size : 86.907 Kb Type : JPG |

|

ISI transformer Extra Information 011217.txt Size : 3.141 Kb Type : txt |

|

ISI Wrong Test 107VAC Out 119VAC In.zip Size : 659.15 Kb Type : zip |

|

3000watt Variac.jpg Size : 36.845 Kb Type : jpg |

My SEM is a ISI SX-30 and predates this ad by one or more years. My column looks different and taller than the ad. I hope that's a good thing.

Update 12/3/14

I purchased a Anatech Hummer VI Sputter Coater on big-auction-site. It is decribed as having a working pump. It is at least 20years old as I see a sticker on the unit which states that the oil was changed in 1994 LOL.

I know it is missing the glass Pyrex (Borosilicate Glass Tempered) and the source disc and holder ("magnatron" or "magnetron"). Sometimes things sit

in my lab waiting on a part or piece which I find later on big-auction-site or sourced from a reader. The

description says that the pump is working and pulls a vacuum. I read

from the downloaded online PDF manual that the interlock wont work without the glass and

without a vacuum. The sputter coater looks to be in good shape. People pull out the source

disc (gold or other metal) before they sell sputter coaters - I see that quite often in my search for a used sputter coater. Its not the source

disc which is precious to me - it is the souce disc holder ( "magnetron" ) which is more

important to me - that is missing too - I only see three ea banana plugs

in the photos - that is where the source disc holder "magnetron" goes.

The

actual gold usually found on these source disc holders is very very thin and the high

price the vendors put on the gold is ridiculous. a 2" dia gold disc with a

thinckness of a piece of paper .004" is $1300. Ebay has gold leaf 24K foil for $1

and is a similar thickness. That can be applied with silver bearing

conductive epoxy. That is is same way the replacement gold discs are

mounted. The sellers of gold discs are raking in the pofits. The only thing I need to be careful about is which gold foil or gold leaf - it is usually coated with wax - so the gold leaf that I find will need to be wax-free. Other metals can also be used like silver or copper.

I

will need to find a glass "Pyrex chamber" and also the source disc holder "magnetron"

The Anatech Hummer VI has a built-in pump which is what I was looking for - something with a pump.

The

school teacher who sold me my ISI SX30 microscope wanted to sell me an enormpous carbon coater for $100 - and I passed

on it because the sheer size/weight of it exceeded my available space. So I feel that I have found

something better now - even though I will need to source replacement

parts or improvise. This is a much better way to do things (for me and for my applications and space requirement) - with a

smaller multifunction sputter coater.

I need to find

A 4" Dia Pyrex Tube (this is an inner diameter and could be greater than 4")

B 2ea Rubber seals for the above Pyrex Tube (I dont have a Pyrex Tube - I seek this) sometimes called L-gasket duy to its shape (pretending as if cross-section view - but it is a continuous ring)

C (Source Disc Holder) "magnetron" or "magnatron" or "target" or "annular ring" etc

Let me kow if you have Anatech Hummer Parts - I think this Pyrex tube and rubber seals and source disc holder "magnetron" is applicable to several models of Anatech sputter coater - let me know if you have used parts for sale.

Also I see some other brands like SPI which have models which use a 4"dia Pyrex glass - let me know if you have 4" dia Pyrex glass from any brand sputter coater (or other application) as I may be able to adapt it to work.

Sometimes high heat OTHER items - like street lights, gas mantle lanterns, custom length tubing etc other scientific applications may be a source for these Pyrex 4" dia tube. It needs to be a pretty hefty wall thickness - let me know what you have. I may be able to cut it to length?

This sputtering technology is sometimes referred to as "DC Magnetron Planar Sputtering"

(The sputter has a mode switch for etching and more - but at this time - my only need is sputtering SEM samples)

|

Technics Hummer Jr on big-auction-site.JPG Size : 135.14 Kb Type : JPG |

I can obtain my own gold from big-auction-site and adhere it with silver bearing conductive epoxy. You can keep the gold and peel it off - if you want to (as thin as tin foil and weighs almost nothing). Let me know if you have this magnetron as pictured above. This picture is a closeup view of a Technics Hummer Jr which I think is exactly the same magnetron as I am looking for.

I dont know the exact diameter of this magnetron - but I estimate it to be about 3" diameter. The center part is approx 2" diameter.

While researching the topic of Anatech Sputter Coater "magnetron" - I have learned that it is not just one piece target holder. There are two pieces - one is an aluminum "Annular Ring" this is the part that has three holes in it and actually contacts the three each banana plugs. The aluminum annular ring looks like a "donut" and is approx 3" dia and has a hole in the center approx 2" dia. The aluminum annular ring is a target for etching (I think) and gets a target bonded to its surface - of the same material as being etched. This annular ring - is offered as a trade-in discount by some SEM parts suppliers. For example if a person buys a new Annular ring from them - and trades in their old one - then they get a small percentage off. I would like to acquire one - I plan to clean the surface and bond my own material to it. If I cant find one - then I will machine one on my lathe.

I see a demo on youtube which shows this annular ring. I am not affiliated with this youtube author. Here is the link to it - look at approx 12:20 for the part about the annular ring and how to remove it. The machine is a different model but is the very same annular disc that I need. (I also need the 2" approx dia center part - I am missing that too)

https://www.youtube.com/watch?v=QJZy3nwu4UE

Update 12/24/14

Here are a few pictures showing what I was looking to use for replacement chamber - but decided against going this route:

I see some sputtering systems on big-auction site which look identical to my own Anatech Hummer VI.

For example "Technics Hummer VI" looks identical and even bears the same model name - but differnt brand name.

I have included a few photos here in a photo gallery - click on the picture to enlarge. Also notics how thick the original Pyrex chamber is - wow that has a thick wall. I dont think the Apothecary bottle will have that thickness!!!

So the parts I need can come from a Anatech or Technics machine. If I cant find the parts - I will try to improvise. The Apothecary bottle seems to be the best improvise material I can find - at this moment.

Here is a youtube video showing a Technics Hummer II (extremely similar to the one I have even though differnt brand and model ) Demonstration

(it is not my video and not affiliated with it)

https://www.youtube.com/watch?v=E-mvUfNHOSM

I found several good sources of the rubber seal that goes above and below the Pyrex Chamber. The lucky words to search for on google or other search engine is "Buna-N (nitrile) Bell Jar Gaskets" or "L-Gasket Bell Jar" When I searched for Pyrex Chamber Seal Sputtering I didnt come up wiuth anything. I tried all combinations of searches and didnt find anything until I used the lucky words. I even see a seller on big-auction site that sells these seals. But first things first - I need to either find a Pyrex cylinder that is the right size or make one myself. I feel better knowing I now know some sources for this gasket in various sizes. I measured my Amatech Hummer (which arrived today all busted) the diamter of the chamber must be 4" ID inside diameter of slightly larger. There is a raised "curb" or bump on the metal plate that it sits on - and that forces the diameter to be 4" or greater for the inside diameter. there is quite a bit of leeway for the wall thickness. I'm thinking it could be drastically greater than 4" inside diameter. I measured my pickle jar and maybe it is too small anyways.

Regarding my Anatech Hummer VI that arrived today - the seller protected he outside of the machine very well (oversized box, lots of pieces of molded styrofoam - like froma TV set, and they packed it well. But they forgot one very important thing - there is a vacuum pump inside and it wasnt bolted down or secured in anyway - so as UPS rolled the box like snowball (out side of the box is round - so that makes me think it was rolled. As UPS rolled the box the vacuum pump was bumping and clanging everywhere on the INSIDE of the Sputter coater. There is a lot of damage. Oil everywhere, styrofoam bits by the thousands everywhere, broken connectors, broken vacuum gauge, bent and scratched and gouged aluminum plates. Yikes.

I spent 2 hours with a vacuum cleaner and rags trying to soak up all the oil and debris. I found some replacement gauges on big-auction-site by searching for "millitorr vacuum gauge" and I see some used ones for approx $40 maybe they work and maybe they dont - who knows. I emailed the sputter coater seller to inform them of the damage. Some sellers are helpful and some are not - I'll see what they say. The $200 I paid is insignificant compared to a new one costing $20k but still - its broken heavily and wiill need alot of TLC to make work again. Which I feel confident that I can get running well. But that will cost additional money to obtain repair parts. Thank goodness for big-auction site - I will just need to hunt for replacement parts for awhile. It is amazing what you find there if you search for it diligently. I'm surprised to find my sputter coater for $99 plus hefty shipping. It is unfortunate it arrived broken. But it is not beyond repair. A brand new on is $20,000 which is way out of ly league pricewise. Used ones with problems are $2,000. Even so my $99 sputter coater is fixable - it wasnt broken when it was at the sellers warehouse- it was damaged by careless packing. I even rushed to the UPS truck when I heard it arrive - so the driver doesnt drop it or roll it. I carried it 40ft and it has a sticker that it weighs over 70 pounds. I didnt want the driver to grab it off the truck and drop it on the ground. I tried to avoid breakage by grabbing myself and carefully caryying it. But the damage was done enroute - and there was no saving it.

Summary of what is broken/bent damaged

1. Oil dumped all over - pump is empty of oil

2. 2ea banana jacks (red and black) and plugs (red and black) busted and bent

3. Aluminum sheet metal gouged and dented in

4. Vacuum gauge moves when you swipe your finger across the plastic bezel faceplate - analog gauge moves to random points when you tap on the faceplate or swipe finger across- I would say this is caused by static charge?? The gauge shouldnt move like that- its broken

5. Metal ring plate which is the sample holder - that is really gouged up and deep gouges like it was dragged across a parking pavement

6. Metal perforated cover has a bent corner

7. Probably more damage than visible - I have not attemped to power-on anything

Also I see there are threaded holes in the sample plate area - probably where some endcaps or vacuum filters go - but those were removed by the seller??

Here is what the L-gaskets look like which I need to buy.

I observed the youtube video (not mine and I'm not affiliated with it)

https://www.youtube.com/watch?v=E-mvUfNHOSM

This video shows a Technics Hummer II which is a very very similar unit - my hunch is it probably has an identical vacuum pump inside. The video shows pumping down from everyday Atmosphere pressure down to vacuum of 100 millitorr and then down to 50 millitorr and then even below.

I timed the number of seconds to pump-down

Atmosphere to 100 millitorr = 10 seconds

Atmosphere to 50 millitorr = 35 seconds

The Pyrex jar shown in the video has a crack in it clearly visible at 0min : 21sec but I'm making an assumption that the crack doesnt impede the pump down. Another assumption is the internal vacuum pump is the same.

My thoughts are that even with a non-working vacuum gauge - it is still possible to manually pump down to proper vacuum by using a stopwatch. The purpose of the pump down to create a vacuum - is only so argon is drawn in to the chamber in the hopes of completely removing air as much as possible. The end result is a Pyrex cylinder which contains argon and is not a full vacuum at all. This purging process of vacuum-then-fill-with-argon is repeated several times in the goal of having pure argon in there without any air - but it just gets you close - but never will get rid of all the air - only minimizes it. Fom what I have read - It is not critical to get out every molecule of air (whether that is correct or not I dont know). I'm sure at molecular level - high quality sputter coating is very important for viewing at high magnifications.

If too high a percentage air remains in the chamber while sputtering - then the coating will be black and sooty oxidized/rusted in appearance. The goal is to have a shiny metal plating of the metal (gold, copper, aluminum, etc) target material. Some trial-and-error is required to figure out how many times to purge the chamber with vacuum-then-argon cycles to give coatings the desired shiny metal appearance. Once I get good results - I will then know how many vaccum-purge cycles it takes.

I see a sticker and notes written on my unit from the previous owner (see photo)

"50-60 millitorr for Au/PD" (I think this stands for Gold Palladium targets which are the most expensive)

"100 millitorr for Carbon"

I dont foresee any need to carbon coat - I passed on that big unit which the seller of my SEM wanted to sell me for $100. I didnt want it as it was huge and I have no use for it and I dont foresee any use for it - for my lab use. Ideally I would like to metal coat objects to be viewed in SEM to increase clarity and sharpness and brightness due to increased conductivity of the metal sputtered object. And most importantly - sputtered objects can be viewed at a higher magnification level in an SEM. My goal is to get to the guaranteed minimum 70 Angstrom maximum that the owners manual states. One comment on the internet puts this microscope at the 60 Angstrom level. I think this Hummer sputter coater is just what I needed. I'm glad to have it.

Update 1/22/15

I contacted Anatech mfg by email requesting quote on replacement parts. I received a pricelist attachment response the same day. I am seriously considering on buying a genuine replacement Chamber for it. I researched online for jerry-rig solutions but viewing a youtube video scared me - when I saw someone homemade canning jar explode under vaccum and plasma arc.

heres the video that scared me about imploding standard glass canning jar

(I'm not affiliated with this video)

https://www.youtube.com/watch?v=bPRmsDx0oYo

So after viewing the above DIY-ers imploded unsafe jar - I am seriously considering to just plunk down the money to buy the real thing - and not have to worry about glass pieces flying at me. Heres the price and parts breakdown that I will need to buy from the mfg.

A. a set of 2ea Gaskets for Pyrex Tube (Anatech part number 1007097 "Chamber Gasket Set - Viton" $60)

B. 1ea Pyrex Glass Cylinder (Anatech part number 1005003 "Chamber 4.5OD x 3.7LG" $130)

They have a $100 minimum order and I was quoted $25 for shipping for just the gasket so it may be more for all of the above.

C. I need more parts but that will suffice for now.

I will also contact international vendors of glass tubes to see what the price is for borosilicate tube. I have purchased a couple of things from aliexpress website and they have alof glass vendors there. Maybe I'll be surprised by their quote either low or high - who knows?

I was looking through my video cameras and lenses and smoke alarms trying to find something that could test my geiger counter. I didnt find anything that would be considered radioactive or hazardous. All I could find is 1 item that clearly shows the geiger counter is working. This item is a 15year old smoke alarm "First Alert" which was retired because it would only use a battery for 3 months and then start beeping requiring a new battery more than typical. I bought replacement units at a department store and they werent much better requiring a new battery at 5-6 months. But anyhow - I still have that old First Alert smoke alarm and when I put the geiger counter on it in various positions trying to elicit a response on the geiger - I can play around with where I place it and can get readings from .22-.36 I was only able to get .36 once and .28 once. the typical number is .22-.26 But this clearly shows the geiger counter does work. And those numbers are approx what other people show on youtube videos. I'm gonna say that this smoke alarm gives somewhere between .22uSv/h and .36uSv/h and that my typical background radiation is somwhere between .08uSv/h and .14uSv/h which is extremely low and actually much lower background than some videos I see on youtube. I feel that I have tested my Bella geiger counter and got some normal readings and I feel confident that it is working correctly. I'm not going to buy any thoriated gas mantle for my lantern - when I do buy a replacement lantern mantle - it will be the non-radioactive current mantles available at department stores. I dont want radiation exposure. I want to avoid it.

Update 1/25/15

Wjhile snowing at 5:30PM I placed my geiger counter in a ziplock bag and then placed it on top of fresh snow in my driveway, under the gutter drain spout, and in my yard always on top of fresh snow. I saw counter per minute betwee 4 and 11 counts so that is definitely not radioactive. My Bella geiger counter only measures Beta and Gamma. It does not measure alpha particles. I was expecting to see much higher counts when I placed it on fresh snow (as per youtube videos - which shows a major amount of radiation in snow) but I saw only normal background radiation - no elevated counts or any other indication of anything radioactive in midwest Illinois. I can only speculate that those youtubers have radon gas coming out of the ground??? Or possibly their geiger counter is contaminated. Who knows. I didnt see any such thing when I measured. Which is a good thing. Im glad there is no radiation around here.

Here is the (non-English) user manual for this geiger counter made approx 1989

Does anyone have the English version manual?

|

Bella.pdf Size : 928.26 Kb Type : pdf |

Update 1/2/14

I have been searching on big-auction-site for many months for a geiger counter and finally made a purchase for a non-functional unit from Ukraine. The photos show the case frontside/backside to be in good condition and battery cover is present. The LCD looks good with no cracks or black smudges - so it apears to be a good candidate for repair.

I have been thinking about sputtering systems and SEM microscopes and tried searching for any documentation or studes regarding xrays, gamma rays, alpha rays, beta rays being emitted from this equipment. I have seen documents from universities stating that this equipment doesnt emit any of these rays. I will fix my geiger counter when it arrives so I can verify my own equipment when it is repaired.

I am glad to find one at a rock bottom price of $10 plus shipping. It is a basic model without frills but I think it will perform the tests I need. The internal sensor tube is SBM-20 which is able to test many types of rays.

Here is some youtube videos (not my videos and I'm not affiliated with it) demonstrating this model Bella (or Benna or Bevva or Genna or Gella - who knows???) or similar model. Some descriptions on the videos state that this geiger counter is for gamma ray testing only. Some other rays dont penetrate the plastic case. I'm particularly interested in xrays and this SBM-20 sensor tube can detect xray particles - and xrays definitely (if present) can penetrate plastic. I think once repaired this unit wil be fine for my needs. Who can argue with $10? I have a soldering iron and plenty of test equipment and a lifetime of aquiring and using components like transistors, resistors, capacitors, etc in small small drawers and boxes. (See my above links at the top of the page "electronic parts testing service" and you will see some of my test equipment and skills.

https://www.youtube.com/watch?v=1LVTPzr342E

https://www.youtube.com/watch?v=9AJMABOhcgI

https://www.youtube.com/watch?v=NX7zBNy7EFY

https://www.youtube.com/watch?v=bU7x7-Jb1yU

https://www.youtube.com/watch?v=eMSWRoGgnNU

https://www.youtube.com/watch?v=pIQcG4IlKK4

https://www.youtube.com/watch?v=Ky0oiB0-sCk

Heres what the make/model looks like in a different language (I dont speak/read that language) frankly I'm surprised copy/paste worked for these words

Dosimeter Bella DBG-01i DBG-01N БЕЛЛА ДБГБ-01И

It looks like a very nicely made geiger counter and has a couple of nice basic features. I look forward to getting it operational and putting it to use. I see alot of youtube videos where people treat radiation as a "toy" but it is not a toy and should be avoided and shielded from coming into contact with people/animals/plants - all living things as this type of radiation damages DNA strands within cells etc. I want to check equipment for particle emissions and if present - then repair/adjust/shield the equipment to be within specifications. According to universities - there is no such emissions from SEM and sputtering systems - but I want to be sure.

I see that the ICs have a unique symbols and numbers written in another language. I researched these numbers and I see that a few of these chips number cross reference to 5400 series TTL logic chips. Very similar to 7400 logic chips except that have a higher thermal operating range. A few websites mention that these chips differ from the standard 7400 series chips by being more radiation tolerant. I'm wondering if the cause of the geiger not working is exposure to radiation affecting the chips. I just ordered this geiger counter yesterday and have not received it. I will see if I can identify the chips. I have a few chiptesters which identify chips whether the model number is printed on them or not. Of course the chip need to work in order to be identified. I may have to unsolder them one-by-one to check them and identify them - which gives a cross reference to standard marked parts.

Most likely it is not the chips at fault as I suspect the capacitors and/or other component has gone bad - or possibly a bad connection or cold solder joint - my point is chips usually are the most reliable parts of any electronic device. It is strange that the seller is selling this geiger counter for $10 when he has SMB tubes and LCD screens for sale separately at a higher price. It might be a can of worms??? with a compilation of bad parts - who knows.

This geiger counter does not sense Alpha rays/particles or Beta rays/particles. I have read online that Alpha and Beta do not penetrate paper or other materials. These Alpha and Beta particles to the best of my research would not penetrate steel or rubber gaskets - so I dont think that the inability of the geiger counter to read Alpha and Beta rays/particles - is not a hinderance and is a non-issue. The geiger counter measures X-rays and Gamma rays - even in a limited capacity of +/- 30% would still be enough to see if a substantial amount is being emitted. My point is that this geiger counter is probably sufficient for my purpose.

I received my Bella Geiger Counter and it was very carefully rolled in heavy cardboard several times and heavy cardboard on each end. It was a very small package and the seller knoew how to ship it. The very first thing I did was throw away the box and take it apart and clan every last bit inside and outside with Q-tips cotton swabs and green cleaner and isopropyl alcohol. Every inch of it was cleaned. It was not dirty - but I cleaned it anyways - because I dont want radiactive dust- who knows where its been - you know? Its a geiger counter - it could have been anywhere - so cleaned it VERY thoroghly.

Inside I found a homemade wiring job - I'm going to call it a KGB gieger counter LOL. Someone put a homemade connector with 6 contacts which were connected to various parts of the circuit board. Before I -un-jerry-rigged it I made a drawing. Just in case I need to put it back or maybe fine some use for it that way.

The connector has 2 jumpers and I found that if I remove 1 jumper the counter still clicks but the number on the screen stay at zero non-incrementing. If I remove the other jumper - then the display is zero and no clicks or any sign of counting. Well I didnt want something hanging off the side of the geiger counter so after I made a detailed drawing- I removed as much as I could.

I still have 2 bodge wires in there- this recreates the 2ea jumper wires that I studied the drawing I made. If these 2 connections are not made - the nothing works. So I shortened the homemade wires.

I'm going to call these 2 points

A. 1 and 16

B. 2 and 15

Hey its my drawing - I can number it however I want LOL. I looked at the connector and numbered it just like IC chip pins are numbered - then I called the point on the circuit board where it connects by that corresponding number. Maybe these points in the circuit board are for leaching a TTL: signal or possibly for a data logger - who knows? I don't need that. there are better geiger counters with that built-in. I just need a basic gener that works - not a KGB agent edition LOL.

Ok well I went around my property and belongings and even measured the vacuum cleaner bag and tool and walls and funace filter and even some times. I just didnt find anything that measures above 14 consistently. Its always different somewhere between 8-14 usually. I have a stack of tiles in my workshop - some are the same as my kitchen as spares and some are just I-dont-know-where they came from because they're all different. Anyways - if I put the geiger counter on the stack of tiles sometimes it goes to 17 soetimes as low as 10 or 12. These readings are really low and definintely not radiactive. I sat down in front of my computer and saw a reading of 8 and then later 12. And in my workshop - I checked every piece of equipment and cans on shelves of paint and gadgets and bolts and even my grinding wheels and sandpaper. I couldnt find anything that gave me anything but low readings 8-14 typically - always different - never the same reading twice.

I even took it outside and took readings on top of the snow in different parts of the yard and driveway and I got low readings of 7 - 12 always different. I even tried putting it on top of 2ea different models of smoke detectors which I took down and set a tabletop and then put the geiger counter on top. I didnt see anything but low readings again 9-14 approx.

I didnt see radioactive snow, I didnt see radiactive airfilters. I didnt see radiactive vacuum cleaner bags. i even checked the screw-on charcoal filter on my sink that filters water - even that didbnt give me anything but "background readings"

One thing that really surprised me was my prpane camping double mantle lantern. I use that regularly - it runs off a propane cylinder just like a blowtorch and it lights up the 2ea "mantles" one of which has a tear in it - but it still works so I just left it that way. It gives enough light. Well I took off the dome cover and the round protective glass and I tried to get the geiger counter to go crazy reading the 2ea mantles. It didnt react to it at all. It was just 12-14 and it wasnt going crazy like I saw on youtube videos. Mine is a used mantle - they are measureing brand new in the package mantles????? Is that the difference - or does my geiger counter need repair? I dont know.

I does seem to count and click and every function works. I fixed the 3ea things wrong with it

1. Someone didnt put the power switch on correctly so when I got it the power switch was "stuck" and I just reassembled it correctly

2. I removed bodge wires and homemade connector - I put it back as much as I could - not having anything as a reference for comparison.

3. Replaced the deteriorated foam

4. I didnt replace the 9v battery clip - that is probably how it came from the factory??

It does apear to work . it does click and give expected background counts typical of what you'd expect. My hunch is that it is working. I may buy a mantle from the store since mine is broken and needs replacing - I could replace it and before I light it -check if I get crazy readings????

The stickers are not paper and this allowed me to clean them thoroughly with isopropyl alcohol. Looks good as new. The circuit board is coated with a clear sealer. Only those areas where the previous owner jerry-rigged it have no sealer. Most of it is protected from corrosion. I cleaned off the flux from the previous owner using paint thinner and isopropyl alcohol. The circuit board looks pretty clean now. Only 2ea wires were used. The rats nest of bodge wires is gone.

An observation about this Bella Geiger Counter

I havent heard of anyone describing a Tic Tic Tic Tic Tic bzzz sound coming from their geiger counter. I notice things like that. When I put the geiger counter to my ear and listen very very closely I hear a ticking sound approx 5 tics per second- roughly 300 tics per minute- thats an estimate I havent counted the tics. The reason I havent counted is because the tics are not loud but the geiger counter BEEP every time it counts a Gamma or Xray particle is loud. I know I could turn off the volume. But I'm just saying there is a tic tic tic bzzz sound. Listen for it - you'll hear it. Its about as loud as a vintage wristwatch. My hunch is that is the SBM-20 tube doing its job. The bzz sound is not the BEEP the bzz is a soft sound and is in time with the counts on tyhe display. Of all the youtube videos and website about geiger counters - noone said naything about a tic tic tic bzzz sound. Aint that something?

Update 1/16/15

I now see why my geiger counter didnt give any readings on my Century Propane double mantle lantern. Newer than 1990 mantles are not radioactive according to a youtube author. That explains why I didnt get any readings. I'm glad they got rid of the radioactive Thorium. My light is bright enough and radioactivity is not what I want.

Here is the video showing mantles comparison. (I am not affiliated with this video. It is not mine)

https://www.youtube.com/watch?v=pOgHciym39U

Isnt it amazing what you find on big-auction-site for $10 plus shipping? LOL

Update 6/2/16

Unfortunately my Bella Geiger

Counter is not working. I wanted to use it to test a CRT inside my film

equipment which scans using a flying spot scanner - when I went to my

cabinet to get my geiger counter - it was in a ziplock bag and no 9V

battery installed. I put a fresh brand new battery in it and I see all

zeros O.O.C.O and one of the zeros is incomplete "C" due to one of the

LED segments unlit. I see no incrementing or tic tic tic. It is

unresponsive. I pressed the zeroing button on top of the unit and red

LED

lit but I see no sensing of background radiation at all. So

unfortunately I was unable to test my CRT inside my film scanner (one of

several extra parts units which I am trying to rebuild/restore/combine

into another good one) which I am currently repairing. I dont know how

it could be non-working as it has been undisturbed in the cabinet and

safely stored. I enjoyed using it and I hope to find time someday to fix

it. I used it about 12 times in the last year and was a very useful

tester. I didnt do anything to cause it to die - was just stored in a

cabinet.

Update 6/7/16