Here is a paypal button for $10 Quote Consultation Fee. This covers my time in phone or email communication. Speaking writing and download/upload photos takes time. I charge for my time and services. This $10 does not apply to any parts or services and is non-refundable. I find that this tends to screen out 99% of emailers/callers. The 1% of emailers/callers are my buyers. I reserve customer service and technical answers to buyers only. I reserve the right to say no thankyou or to charge more due to the complexity of the question etc. I perform repairs and or diagnostics service for -circuit boards/parts etc. BUT no repairs and no diagnostics testing services are included in this $10 Quote Consultation fee.

Dr Virago Pete's Electronic Parts Testing Service

Send your desoldered components ready for test

1. Desoldered

2. Wrapped carefully

3. Return envelope and postage affixed

Solid state & Semiconductor Components I can Test

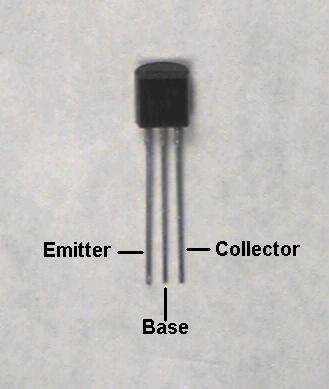

1. Transistor

a. NPN & PNP

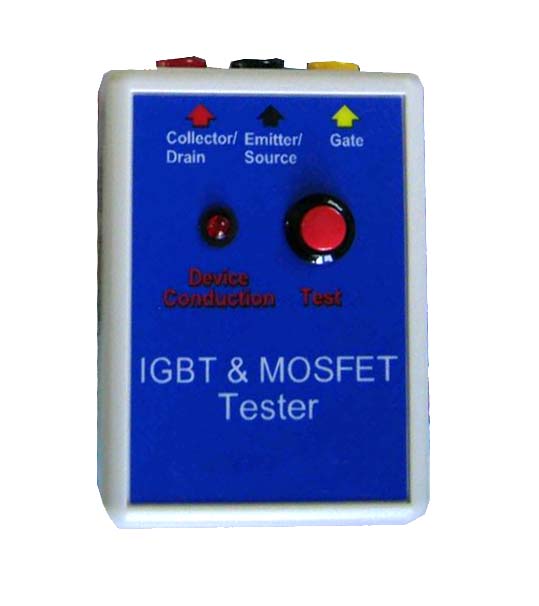

b. Mosfet

c. IGBT

d. Power

e. others

2. Diode

a. Germanium

b. Silicon

c. Zener

3. Capacitor

a. Capacitance

b. ESR

4. Inductor

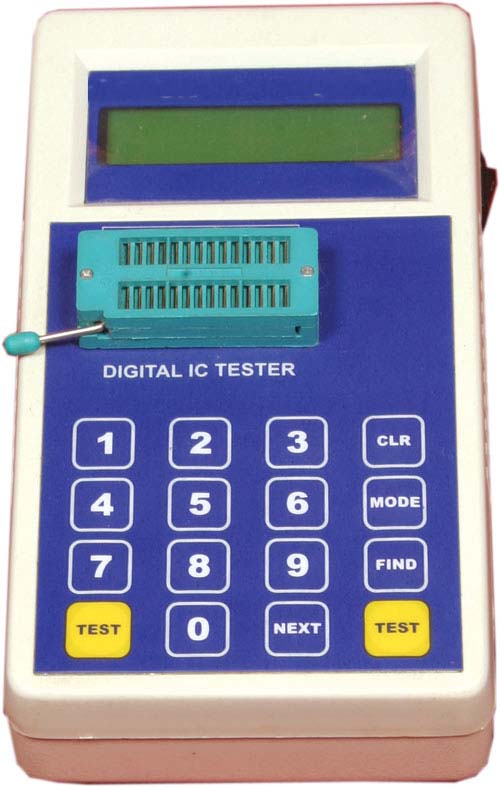

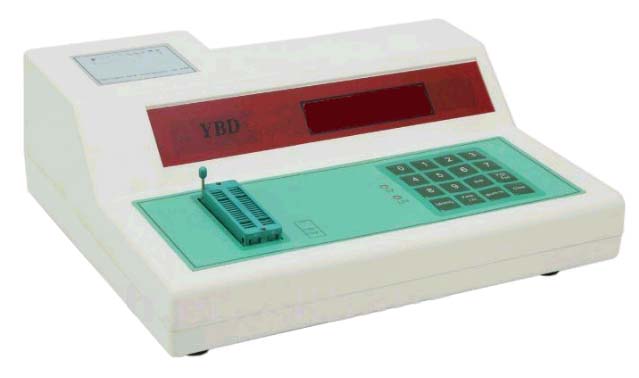

5. IC Chip

a. TTL Logic Chips

b. 7400 series chips

c. 5400 series chips

d. 4000 series chips / CD4000 series chips

e. HEF400 series chips

f. 4500 series chips

g. ULN series chips

h. others

6. Voltage Regulator

a. 7800 series

c. 7900 series

7. Varistor

8. Optocoupler

9. Solenoid

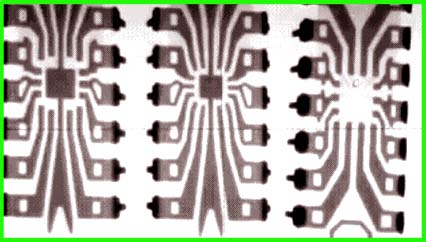

10. Surface mount components / SMD.

11 Analog Chips

This ad is aimed at the DIY student or hobbyist who is working on his/her own electronic device and needs assistance in troubleshooting.

Consumer-level meters simply do not have the ability to thoroughly test solid state electronics. For example the average multimeter can only test Volts and Ohms.

Intermediate level meters can check capacitance but not ESR. These intermediate level meters can test transistor gain but not leakage. This leads to frustration in the student or DIY repairman/woman because they are looking for a fault they cannot find.

I have professional test equipment which can thoroughly test components you send me for test. Most components on a PCB are soldered in place. You must carefully desolder components before sending them for test.

Identification of Unmarked components

1. Scratched off markings

2. Worn ratings number

3. IC chips

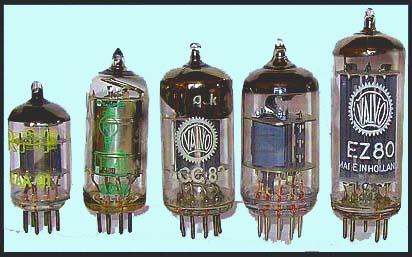

I am looking for a "U-TEST-M" vacuum tube tester made by Colonial Merchandising model 2500 and when I purchase one - I will update this ad to include vacuum tube testing service also.

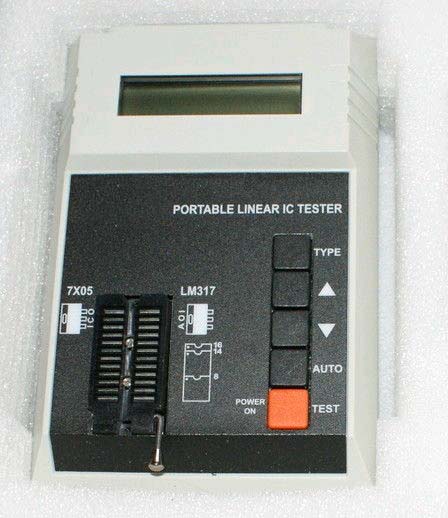

I am looking for a "Linear IC Tester" or "Universal IC Tester" and when I purchase one or more I will add this to my list of chips.

There are many parts I have in stock as replacements and some that I do not have in stock. I also have many books which show the ratings of thousands of parts. I can also cross reference substitutes and replacement parts.

I can identify a replacement/substitute for most parts.

What Makes Dr Virago Pete Qualified?

1. I own many parts checkers and testers

2. 30+ years experience in troubleshooting electronics

3. Former Electronics Instructor

Tips

1. Always put your IC chips in sockets when building a kit

2. If your device runs on batteries - dont run off power adapter

3. Use a correct soldering iron 15watts or less

4. Learn to desolder quickly without overheating your parts.

5. Take a detailed photograph of your PCB and make notes and sketches before desoldering anything from the board.

6. Don't tinker - do it the right way - or don't do it at all

Contact me if you

need chips or other electronic components tested. I try to be reasonably

priced. Many electronic devices made in the 1970s, 1980s, 1990s, 2000s,

2010s used off-the-shelf stock chips for all or a portion of their

functions. I can test these industry-standard parts.

What I'm trying to say is - when you are repairing a device - finding the 1 bad component - whether it is an IC chip or other - you hope that it will be a common part that failed - one that you can easily replace and is readily available. Most likely your device has failed in one or more common parts - cheap to replace - but the trouble is - in identifying which one has failed.

The number one cause of failures in electronic devices is electrolytic capacitors (sometimes obvious due to the bulge) and sometimes tantalum capacitors will spontaneously cease to function or pop/explode - as these can fail quickly - sometimes while letting out a very foul smell unique to a dying tantalum capacitor (several aerospace companies refuse to use tantalum caps in their space missions)

I can test

capacitors with my professional ESR tester. Bad capacitors do not always

bulge. Sometimes electrolytic capacitors will make a loud POP like a firecracker as it is dead - bulging the top or not bulging the top. Most failures are not dramatic and make no noise or smoke or smell. Equipment is necessary to identify these bad components without visible clues - which is where my expertise comes in.

Dr Virago Pete

(847) 454-7858 between 11am and 7pm daily

email address drviragopete@att.net

Located in Illinois USA

My assistance is not free - reasonable fee - call to inquire.

I use quite a few desoldering methods and decided to add some insights about my Soldering / desoldering equipment. I normally use a Radioo Shack desoldering iron with red bulb for my everyday desoldering of parts, but occasionally I will have a particularly stubborn or delicate part and I am always looking for alternative ways of desoldering parts.

I have the following Soldering / Desoldering equipment

1. Radio Shack 15/30 watt switchable soldering iron (the one I use the most) 120V I have went through a few tip as they tend to get eaten away by solder and flux. I also use a fine metal file to clean it up when the tip gets nasty. I like when the tip gets short as it heats better. When the tip is new and long it doesnt heat as well as when it is short. I dont often sharpen the tip - only when I have a very delicate soldering job like high-pin-count ICs. The tips unscrew so it is possible to change between semi worn tips and brand new ones. I usually keep a spare tip in my soldering tool box. Previous to this I used a gun handle style soldering iron from Radio Shack approx 30 watts which I liked also but burned out after 10 years of use - not a bad reflection of the mfg at all.

2. Radio Shack 45 watt desoldering iron with red rubber bulb (the one I use the most) this is my second unit as the first one burned out after 15years of regular use which was very reliable and hardworking. 120V I have went through a few tip as they tend to get eaten away by the solder and flux over a long period of years. I usually keep an extra tip in my soldering tool box.

3. Radio Shack Portasol Butane soldering iron - purchased used (tip burned out after 10 years of regular use - I bought an aftermarket brand new in the package Boardworks tip for it (with slots rather than original keyhole shape - and the slotted tip burned out after 1 week of light occasional use) I still have not ordered a replacement original tip as I dont want to keep throwing money at this tip replacement issue - which the tips are expensive. Was very useful for soldering PCB with very large amounts of solder or where high heat is needed - like to reattach coaxial connector on RF shield - where a normal soldering iron just doesnt have the muscle to heat. I like this unit and the burned out tip isnt a bad reflection on the mfg as I got 10 hardworking occasional use years out of that standard tip that it came with. 60watts approx heat output with standard tip. I replaced the flint with a standard Robinson lighter flint as it was worn out from my use and the previous owners use. Update 10/4/16 I have purchased a set of 4ea tips for Portasol and to my amazement - the brand new soldering tip didnt work good after 3-4 soldering sessions - making sooty big flame when lit, sputtering, not glowing red hot, flakey and difficult to get it to work - WELL here is why and how I fixed this issue. See Butane turns into water as a chemical reaction. Over time (my Portasol is over 10years old and used very often - NICE TOOL) there are water droplets/trapped air etc inside the unit. I fixed my unit to much improved but still not perfect condition by using a 1/8" metal rod (Dremel tool end shaft) to push up on the butane fill valve. FFFFFFSSSSSSSFFFFSSSS the butane sprays out the bottom (wear rubber gloves) and this pushed out the water and air. The next time I used the Portasol - it worked and lit much better. I may have to repeat this step to fully get out the contaminants. Dont get me wrong I really like this soldering iron. Its not the fault of the unit or the butane from the hardware store. Butane itself turns into water and collects inside over time - just like a pair of glasses gets condensation coming into the warm from the outside cold winter air. Butane is a gas and gets compressed- when sprays out - it is very cold- thats where the water comes from combustion and also the cold/hot/cold/hot ... condensation.

4. Tenma desoldering tweezers 21-8230 purchased from big-auction site) and I made a few custom-made tips to remove ICs with it. 45watts 120V I like the dual soldering iron design and see my other page for the tips that I custom made for my unit.

http://www.drviragopete.com/ic-desoldering.php

5. Hakko 470 desoldering station with 803 gun (I bought used and doesnt work quite right- temp adjustment even on highest setting doesnt melt some high temp solder but still work fine for normal good type solder but heating could be better - possibly needs adjustment or a weak/worn electronic component inside) This is not a bad reflection of the mfg as it is 20+ years old and Im not the original owner - I have a spare gun and purchased some oddball things it was missing from big-auction-site like solder reservoir spring, and ceramic filters. These little parts are very expensive and I was glad to buy this used unit for a low price on auction- but the little missing/replacement parts pieces add up very quickly in cost. Most electronics enthusiests are nortoriously little-or-no-cost $ spenders. 120V adjustable heat

6. Weller blue adjustable temp Soldering Station WSD80 - in disrepair/disassembled - purchased it that way from an online auction. A restoration project I hope to find time for. It looks like a good unit and the disrepair is not a bad reflection of the Mfg. It is over 15 years old and who knows how much the previous owner used it? My hunch is it is approx 80watts max of heat with the iron I have and is temperature adjustable. I dont know what is wrong with it at this time as it is disassembled and never been plugged in by me.

7. China Imported Blue/White desoldering iron solder sucker 220v 30Watt - never used as it runs on 220v not 110V

Update 5/5/16

I recently purchased a very inexpensive desoldering iron with built-in solder sucker pump (see picture blue/white unit above) and decided to purchase from a California big-auction-site seller. I received the unit in about a week and was just like some of the youtube videos which shows the product. I decided to disassemble the electrical cover just behind the push down lever and I see 2ea bare wires (just like the video) and I also measured the ground aligator clip end and I see no continuity between the hot tip and ac prongs or ground wire - I checked every combination. So the alligator clip ground is non-fuctional. I also spent time researching this item in forums and on youtube videos and there seems to be some confusion on whether this advertised 220V 30W unit works on standard household 120V (as it does have a normal 120V plug) and so I plugged it into my household ac outlet (measures between 123V to 126V AC typically) and the unit does heat up but never sufficiently to melt solder- even after leaving it for an hour. So it gets hot enough to burn your hand but not enough for solder melting on 120V. I was also under the wrong impression by the ad that it runs on normal household ac - but I did see the 220V in the ad also. So to put aside the confusion, I am posting this short article about it. I am still glad to have it even though I have not actually melted any solder with it. It came with a cleaning rod and 2 total tips - one with a fine time and one with a bigger hole. I plan on buying a small travel power adapter which converts 120 to 220 AC to use with this unit. Alternatively, I could disassemble and add nichrome wire in the correct amount to make it standalone 120V but I think I will just buy a cheap small travel adapter as a better solution. Maybe in the future they will make one that runs off of 120V standalone.

You would think that a 220V 30Watt de-soldering iron running on 120V would be a 15watt - BUT NO - it is not like that at all. It simply does not heat sufficiently at 120V. This is not a fault of the mfg but rather a miswording of the advertisement. The only fault of the mfg is the ground alligator clip which is non-functional. Frankly - few soldering irons have a ground wire and are mostly 2-prong. So having a non-fuctional alligator clip leaves me to either snip it off or attach it properly or leave it as-it-is. I havent decided on that part. For now I put it back in its package and will just add it to my close full of electronic gear and parts and stuff- which I use on special occasion. I was planning on using this to fix a particularly stubborn power inverter where the through holes are barely big enough for mosfet legs to squeeze through and they used hard to melt junky solder. I was hoping to find a better desoldering method for these difficult oddball boards - but alas this desoldering pump iron combo wont work on my 120V ac outlet. So until I get a step-up transformer of some sort- I cant actually use it. I only paid a few dollars for it- so Im still glad to have it and someday I may wish I bought a spare - who knows I may find a use for it. No holder was included and it seems to be balanced where if I lay it on the table - the tip doesnt touch the table - but still I will use a small Radioshack bent-piece-of-sheetmetal style soldering iron holder which I already have.

I see that some USA sellers have a "Tenma" model which is Yellow and White - and is probably color coded - Yellow unit for 120V and Blue unit for 220V. So I probably just bought the wrong color. Read the ad because it is possible that the color of the unit does not always match the voltage.

I like to use the bent piece of sheetmetal style soldering iron holder as it has very little contact with the hot iron and so doesnt rob the heat from the iron. I also have a Weller holder and soldering iron which is not functional and I bought it disassembled (previous owner repair attempt?) from a big-auction-site - but have never attempted to repair it - not enough time in a day/funds to get to all projects unfortunately.

I dont leave my soldering irons & desoldering irons running idle - I unplug them when not in use and plug them in just as I need them - letting it warm up for 10-15 minutes before use. This prolongs the heating element life and saves on utility bills cost- that is my personal view and you may disagree - as some people feel leaving electronic equipment like computers on prolongs their life (I disagree) and that the power cycling on/off is what actually shortens the life of equipment. You can have a different view - no problem. I always unplug my electronics when not in use.

Update 5/19/16

After about 10 years of having purchased and not assembling a used Weller WD80 soldering statiion (purchased nonworking and disassembled) I decided to work on it today. I cleaned all the individual parts using a bottle of dilluted green cleaner and water and spray bottle which I used for that cleaning fluid. I noticed that the previous owner boogered up some parts like the digital temp buttons are mashed and solder dings and the case has been exposed to alot of flux over the years and is splotchy- but I cleaned it up and looks better than before but not perfect. The transformer is mounted to the case bottom and plastic had a crack so i switched the ground wires to a screw closer to the the front of the unit which allows the back screw to screw down further and grips the remaining plastic hole and holds the cracked case better. I bent the sheetmetal heatsink away from the board - to a 90degree angle. I used my Capanalyzer to check all the capacitors and I did find one SMD electrolytic which had an ESR of 10 and an adjacent identical which measured 3. But I left it alone. I also checked the diodes SMD style and found none that triggered the ESR meters alarm. I used my Fluke 73 multimeter in diode check mode to check all the diodes and found none shorted and I also checked the 2ea TO220 package devices (possibly transistors- I didnt need to check) for shorts between legs and found no shorts. At that point I reseated all of the clips to make sure good connections. I also removed the fuse from the AC rear plug jack. The fuse tested good removed. I reinserted after bending the fuse holder 2 pins straight as it was a little cockeyed. I used the Fluke meter's continuity check to systematically check the AC prong and input lines to make sure fuse and continuity from AC cord was valid. I powered the unit up disassembled - making sure nothing electrical touched while live. I found that the Weller WD80 does not power up while the soldering iron is not plugged in. When I powered off and connected the soldering iron - then repowered on - then the digital display lit and the soldering iron heated and maintained whatever temp I selected. I carefully bent the heatsink back to straight and reassembled. Later that day I used it to desolder some N-Channel surface mount FETs from a non-working motherboard and tried various heat settings from 500-700.

I have decided to purchase a handheld hot air tool today GJ-8018LCD purchased from China seller on Big-Auction-Site. It was a pretty good deal at $34.57 for the 110V 200watt version, and I look forward to receiving it. I have an upcoming project of replacing some surface mount components for a 3000watt Power inverter for someone and this is a good time to add this tool to my vast tool inventory. The miniature surface mount components were provided by the mfg and if it were just one or two- I could get by without this tool. But due to quite a few that need to be replaced- this time saving tool is necessary. Also, I am interested in plastic welding- and this looks like it could be suitable for plastic welding rod for repairs of big plastic items such as car bumper, garbage can, snowmobile hood, etc. I dont work on those type of things- but I have been thinking about disassembling some motorcycle batteries that have a bad cell- so being able to weld the case back together is on my mind. Also, I decided to replace my non-working Radio Shack Portasol (very trusty for many years but died awhile back) with a $30 Portasol P-1 I found brand new on Big-Auction-Site. These purchases are a splurge since the upcoming project covers these costs - and will come in handy to perform the repairs on the 3000w power inverter. The Portasol is especially good at heating large solder islands - which smaller soldering irons have a really hard time with. I like how my old Portasol made a nice neat job of smoothing out the large amounts of solder on these BIG areas of solder - very pretty end result.

I have had no-problems-that-come-to-mind about ordering directly from China. The parts and supplies and equipment are usually pretty good, decent and just what I expected. I see some youtube videos about repairs about this item. Hopefully, mine will last a good long time. After watching some videos about this GJ-8018LCD unit- there was one that mentioned the need to observe correct shutdown procedure- turn temperature dial to lowest setting and internal fan to highest setting - just before you turn off power switch. This is to evacuate all or most of the heat from inside. Otherwise the heat has nowhere to go when it is powered off abruptly.

Update 1/22/18

There is a decal on the unit which states - to let the unit cool down to 30 degrees C before you turn off. I suspect that if you shut off with inernals hot - that you would melt something inside - like the case and or fan etc and cause severe damage. I have experimented with my fixed unit and works fine now and I let it cool down to 26 deg C before I shut down- this caused no harm and the next time(s) for using it - worked fine.

It is my experience that SMD chips and SMD components usually dont go bad too often. I havent run into a big need for a hot air station or hot air tool. Usually in those equipment that I repair - it is some discreet/through hole component like transistor or mosfet or capacitor that has gone bad. But since someone is sending me their 3000W power inverter and a whole lot of parts they want replaced (the Mfg provided them all) then thats what have to do for that buyer.

Update 1/21/18

I have received my GJ8018LCD Hot Air desoldering/soldering tool and had some issues from the factory that needed repair. I think it is a worthwhile good tool. Unfortunately I got a bad one- unlucky for me - but I still recommend getting one.

I see a schematic on a video which helped me identify DB3 as a real part number (as I looked through the magnifier I was not sure if it was a D or a O or a B or an 8). I am not affiliated with this video- not my video.

https://www.youtube.com/watch?v=dqsT3PNfj7Y

I suggest opening it up to make sure to correct any mistakes in assembly. I have repaired it and my story/pictorial is herein these files. Contains photos, a text file, 3d printable hole cover STL file and CAD drawing of this part. I created this modification/repair Jan 2018.

|

My GL8018LCD Repair Part A.zip Size : 13704.479 Kb Type : zip |

|

My GL8018LCD Repair Part B.zip Size : 14591.316 Kb Type : zip |

|

GJ8018 PCB & Wiring Sketch.jpg Size : 1449.306 Kb Type : jpg |

Doma / Amscope Stereo Microscope (heavily modified)

I use a plastic stereo microscope which is Amscope model SE120 and has 20X magnification. It had a strange design in which I feel it was made Backwards. So I cut it in half carefully and made it Normal.

This microscope was purchased in 6/2018 brand new directly from Amscope (Arrived in a crinkled Doma 210 box.) There were other no-name for the same price, but the photo showed this unit with the rubber eyepieces - that was the deciding factor in going with Amscope. I dont know whether the no-name units came with rubber eyecups or not.

I modified it the same day I received it using a 3d Printing Pen and light gray ABS filament. The body of the microscope is white and I used ABS filament which I already had. I wasnt worried about a color match. I made a big ugly weld and went over and over and over as I wanted it to be super strong. Im sure the DIY weld is very ugly and very strong.

I used a dot placed on the stage as a target (piece of tape with a magic marker dot) - welding the plastic and comparing the dot often to see if it is in the center. This took several tries to get right and I ended up cutting my own plastic welds and re-weldind it until it was centered. This tedious process took about 3 hours and Im pleased that I have a nice straight level NOT-BACKWARDS-ANYMORE microscope. I specifically purchased this to reCAP a Panasonic DVCPRO50 VTR that I own that was just FULL of Bad SMD electrolytic capacitors. In the waiting period for the arrival of the microscope, I have re-done most SMD caps with just a filmstrip projector lens- but was very tedious. I will be using this microscope from now on.

Amscope SE120 (heavily Modded) has a bright single LED and runs on 2ea AA batteries (supplied). I even modified the styrofoam box - so the same microscope fits into its original crinkled DOMA 210 box when not in use. THUMBS DOWN ON A BACKWARDS microscope that came in a wrinkled box with a different brand. I corrected it to be NORMAL and now works good and feels good. The rubber capstan-style up/down movement doesnt hold the position as firmly as I would like. For now it is good enough and holds up/down position good enough to solder/desolder.

I see the very same big-auction-site ad where I bought mine a week ago - it shows qty 810ea sold so far and seems to be a very popular microscope. I wonder if Amscope is a re-brand or the actual mfg?

I see the same microscope "Aomekie" "Amscope" "Doma" and some no-names. My box shows "DOMA 210" I have created this image using Microsoft Paint on a Windows XP laptop. The gray blob represents my plastic welding using 3D Printing Pen and ABS filament.

Here is a photo pictorial of my Modification to the microscope. See the above photo shows the eyepieces are facing the wrong direction. My microscope has the eye pieces facing the other way now (took me 3 hours to fix it) and the ZIP files show every step.

Update 8/18/18

As a result of extensive SMD capcitor replacing and using this heavily modified microscope, I have become painfully aware of the shortcomings of using SMD solder paste. Previously, I just thought it was a liquid that had te color of solder and magically turned into solder when heated- this is now VERY aparent to me to be false. As I look at my soldering under the microscope I see that the paste is actually tiny balls (like a bottle full of BBs or ball-brearings and it has a poor quality flux that evaporates and dries out- this flux is unlike traditional soldering flux. The SMD Flux Sucks!!!!! The microscopic balls fly everywhere when you put your soldering tip to melt it. Under the microscope it makes a big mess. MESS MESSS MESS I couldnt believe what I saw under the microcope at 20X magnification. Wiping the excess SMD solder with a cotton swab just smears it everywhere.

To the naked eye, soldering SMD is nice and neat and clean- but under the microscope - I see that it throws microscopic lead balls everywhere on the board and more. Also as I view youtube soldering videos - I am noticing that this happens to everyone and they are oblivious to the lead balls flying while they are soldering SMD. As I watch closely in these online videos I see these solder balls flying and the authors are oblivious.

I havent read or seen ANYONE addressing this issue.

My solution is to vacuum these ridiculous solder balls using a 3d printed attachment for a small Shopvac.

I will chronicle this further down on this page.

|

Amscope 120 Backwards Mod Part1.zip Size : 11075.551 Kb Type : zip |

|

Amscope 120 Backwards Mod Part2.zip Size : 10220.89 Kb Type : zip |

Vacuum Cleaner Attachment for SMD Solder Ball Cleanup

I have designed and 3d printed the following items using freeware Solvespace and an older Windows XP laptop. I printed them in ABS on a heavily modified Alunar R100 3d printer with a cardboard pizza-box enclosure and Add-on heated printbed. I printed these pieces solid and .1mm resoolution and Elmers Purple gluestick on a plain aluminum heated bed. I used Cura to generate my G-code. My process is painfully slow but gives wonderful results.

I have included one photo showing the hose attachment and interconnects/couplers for as many BIC pen tubes as I need. Sometimes I use this for cleaning hard to reach machine internals. Sometimes I use it to clean circuitboards Im soldering SMD which throws alot of microscopic solderballs everywhere - even in between solder legs and hard to get to places.

The bic pen tube tip can be with or without the black or blue pen tip. For cleaning microscopic SMD solder balls - using the black or blue pen tip allows for a much smaller vacuum hole- and hence more powerful suction in a small spot.

I dont know where the balls go when sucked up inside the machine- it would be good to invent a solder ball catch filter etc which goes inside the vacuum cleaner. I dont know if the vacuum cleaner bag will catch these tiny solder balls. I dont know whether the vacuum cleaner with throw these solder balls everywhere in your room. Some vacuum cleaners have a bag and others do not. Use your own best judgement on whether this is right for your application or not. Spewing tiny lead soldering balls in your lungs and all over your room - is not what I want for you. Be safe.

Be aware that lead solder paste is absolutely packed with tiny lead balls which get sprayed everywhere as you solder. All over your hands, clothes, floor, walls, PCB, etc. Look under the microscope and you will see Im right.

Use at your own risk.

|

Vacuum to BIC pen(s) files Dr Virago Pete 081718.zip Size : 55.966 Kb Type : zip |

------------------------------------------------------------------------------------------------

Electrolytic Capacitors go bad and are the #1 Cause of Failure

(My Personal View)

Electrolytic Capacitors have a rated lifespan of approx 1000 hours or in the case of highest quality electrolytic capacitors 2000+ hours rated. Multiply 24hours in a day x 30days in a month and you get = 720 hours in one month. So really 90days is the rated life of any device which contains electrolytic capacitors. That is one reason why Manufacturers only offer a 90 day warrnty on TV sets etc- if you leave your TV set on continuously for 90days straight - it will most likely survive 90days without fail- so the mfg is fairly safe offering a 90 day warranty.

It

is amazing that so many devices lifespan is greater than 90days - it

really is not supposed to last that long. Care in handling and not

letting a device get too hot - helps extend the life.

My point is that I always unplug my devices when not in use - any device - especially one where it contains capacitors.

24hours x 30days = 720 hours in a month

3 months x 720 hours = 2160 hours in 3 months

There is some truth to power cycles shortening the lifespan of a device. But I still turn my devices fully off when not in use. Some devices have a standby circuit waiting for a remote control command or a pushbutton command to fully power on- but still a portion of that device is on - even when it is "off" My personal view is - it is better to fully unplug it (or switch off power switch to the outlet or power strip) to prolong the lifespan of the device.

|

Eds88Aom.pdf Size : 112.445 Kb Type : pdf |

|

EDS Capanalyzer ad.JPG Size : 301.264 Kb Type : JPG |

The above is an ESR tester - EDS-88A CapAnalyzer (Series II) which tests ESR (equivalent Series Resistance) for electrolytic capacitors and other types such as tantalum and more. The above file is the user manual. My ESR meter is the EDS-88AII which is a slightly more recent design. The LED bargraph display is easy to read and the alarm sound is settable by the linear potentiometer for sensitivity. The best feature is its automatic self-discharge of capacitors. That was its biggest selling point to me and a big time saver. It will cycle through self-test and several other checks before each and every capacitor check. It is a quick machine and has found countless bad capacitors. An excellent ESR tester.

I already know where the bar graph LEDs should be for small through large capacitors so I dont need to refer to the chart anymore. I just know when the bargraph looks odd for a capacitor then I know it is time to change it. Also comparing the same size capacitor over the same to-be-repaired-board will make a few stand out as being weak or odd functioning. It is a true in-circuit tester. Some bad capacitors show a led towards the bottom of the bar-graph or dont register at all. Slightly weak capacitors can be just a little higher or lower than should be- those are generally not the cause of a failure in equipment operating. It is the capacitors which deviate drastically that generally are the cause of equipment failure to function etc. I always check my new parts too because there are sometimes duds in brand new capacitors purchased in bulk.

Finding a bad capacitor is not about nit-picking if it is in the red or yellow or green area of the chart. A bad capacitor will be blatently bad. If it is not blatently bad then most likely - that capacitor is not causing your equipment to have failed to work.

A bad capacitor will usually be 2x or 3x or more - the rated esr of the rest of the caps you test which are of similar size/type. It will be blatently bad or will give a no reading or a alarm or be drastically different than the rest of the caps.

Cracked or bulged caps or caps which leak gunk (flux) or fluid (flux) are definitely bad and should be replaced- even if they test fine. Some capacitors are glued by the factory - dont mistake glue for leaking flux.

I dont recommend powering up the tester with the red button held down- this disables the self discharge feature (until next power off) because self-discharge is a protection for your esr tester. Touching a charged capacitor can kill the esr tester. Even though it takes an extra second to automatically discharge.

The tester needs no polarity as it functions with self-generated AC frequency and AC is non-polarized. What that means is that you can test an electrolytic capacitor either-way -either polarity of the black/red lead is fine and doesnt matter to the tester which way you connect it to the polarized cap.

It is important not to test huge capacitors with this tester. Just normal size or small capacitors as found in everyday electronic devices like TV radio computers and other ordinary household type equipment. It is not for big high-powered capacitors.

Capacitors generally have a 2000 hour lifespan. It is a wonder most electronics lasts longer than 90days because that is the warranty period. Capacitor's 2000 hour life is 90days. It is a wonder that devices like tv sets last longer than 90days. I always shut off my equipment and appliances and audio/visual gear & more when not in use. Why waste the life of your equipment - by just letting it run idle?

Runs on 1ea 9V battery. Purchased used in 2011 year. A similar tester is Capanalyzer Model EDS-88A

Some notes on difference between model EDS-88A and EDS-88A series II:

The series II has the words "Series II" written on the PCB. The series II uses 2ea PIC chips. The EDS-88A uses 1ea Pic chip and 2ea large LM chips. These 2ea large LM chips were replaced by 1ea PIC in the Series II. The components and layout are very similar. Identical functioning. I have seen a model EDS-88A with a slot cut in the back with a prop-up style holder (See picture file). My newer style EDS-88A Series II does not have this slot or holder.

I see a big-auction-site listing where EDS was cleaning out their inventory of spare parts on 6/22/15 and feel this partial parts list is very important in case of a need to replace blown components. I have copy/pasted this partial parts list here. The ad showed parts used in the Leekseeker89 and Capanalyzer.

|

Text from EDS ebay ad 062215 for spare parts inventory.txt Size : 1.776 Kb Type : txt |

|

Big Auction Site ad from EDS for spare parts inventory part A.JPG Size : 60.524 Kb Type : JPG |

|

Big Auction Site ad from EDS for spare parts inventory part B.JPG Size : 98.711 Kb Type : JPG |

|

Text EDS Probes Excess inventory Ebay sale 062115.txt Size : 0.751 Kb Type : txt |

|

Capanalyzer Probe Kit ad 062215.JPG Size : 75.475 Kb Type : JPG |

|

Lot of 100 Probes.JPG Size : 174.149 Kb Type : JPG |

|

Capanalyzer EDS88A with slot and Prop-up Holder.JPG Size : 234.715 Kb Type : JPG |

|

Capanalyzer EDS88A with slot and Prop-up Holder inside view.JPG Size : 263.061 Kb Type : JPG |

Several photos showing transistors, capacitors, diodes (above pictured)

I received this book for free from a local electronics store that I used to buy parts from regularly in the 1990s. That store is now closed and the remaining branch is too far away to drive to but I occasionally mail order from them still. This book is old and the tattered pages and cover are taped back together. I use this book often. When I suspect a part is bad - I look up the part number in this book and it tells the specifications of the cross reference part in great detail. At the front of the book - a list of available replacement semiconductors is handy. It also contains drawings of pinouts.

ECG parts and NTE parts share the same part numbers and specifications - so when I find that I need a replacement - I will look online or call local electronics stores with a part number. I tell them it can be ECG123 or NTE123 for example. I sometimes can find a replacement part still in its package unused on big-auction-site. It is amazing that one little part can cost 2-10+ bucks each and even so the repair of that device for $10 is money well spent and very cost effective. I sometimes look for a reverse cross reference so I can broaden my options when buying a replacement part. There are millions of numbers that truly are the equivalent part. This book narrows down those millions of numbers down into several hundred part numbers.

The main pupose for this book - for me - is to compare questionable parts and decide if the part is still good. This book has saved me from buying a large quantity of replacement parts over the years. I can key-in on only buying parts that I know are truly in need of replacement.

My cat starting digging at this book 5 years ago and luckily I caught it just in time - before she tore it to bits. The cover and a few pages-in are now taped back together as best as I could. The holes are due to my cat. The worn out pages are due to my extensive use of this guide.

I purchased this tester approx 1997 brand new and been using it for over 15 years. This tester is a full service device and fully tests out-of-circuit/desoldered transistors, Diodes, SCR, LED, Resistors, Capacitors (Capacitance value only - no ESR), batteries, etc. This device helped me repair quite alot of electronics. The only test that it doesnt do is ESR which I believe this machine was made before ESR testing method was invented. I use this tester in conjunction with a 1996 edition manual to look up the cross reference value of nearly any semiconductor. Then I compare those specifications to what this BK Precision 815 Parts tester reads from the questionable part. I have purchased a few NTE and ECG replacement parts based soley on the readings of this tester. It has never let me down and is always correct. I have read alot of questionable parts on this tester and resoldered them back in circuit knowing that this tester proved the part in question was not bad after all. It has saved me from buying replacement parts un-necessarily. I can key-in on ONLY buying a replacement part which are for sure needed.

The above pictured tester shows a rubber protective cover. Mine was one of the first ones made and didnt come with that rubber cover. It still sells for the same price that it did 15 years ago. For the last few SCRs that I tested - I couldnt get my meter to over-range (the first 2 tests pass and the last test fails to over-range). So I ended up buying an SCR twice un-necessarily. I'm starting to think there may be a component inside that has gone bad. Fixing a tester is one of the hardest things to do. You need a tester to test a tester ... and if you rely on that tester and you only have one - then ... I'm not truly convinced yet that it doesnt work for SCR anymore. I will refrain from repairing that which works. It may be that those 2 SCRs fooled it or it may be that the tester has a bad part - I'm still undecided. If the reader has a suggestion on which internal component to check - let me know. The Duoyi DY294 shares many of the same functions - so I am able to test my tester with a tester ... LOL

I remember seeing a bright yellow Clone of this tester on big-auction-site. Unfortuantely I no longer have that photo.

|

DY294_V3.pdf Size : 139.275 Kb Type : pdf |

Above pictured Duoyi DY294 Transistor & Parameter Tester (Also Checks many other semiconductors and capacitors etc)

DY294 English manual download above (my tester came with a foreign language paper instructions)

This tester has some unique features which allow me to test parts I could not otherwise test. It also internally scales up the voltage for certain tests- for example it can generate over a thousand volts for certain tests yet only 4ea AA batteries power this tester. It tests alot of parts' parameters so it can be compared to book specifications. For example when deciding whether the part is good/bad - comparison of data found in ECG or NTE semicoductor replacement data books - comparing what you see on this tester can be compared with those listed in the ECG or NTE books for their subtitute cross reference part values.

Some tests for varistors or transistors with internal diodes can be checked with this tester. It is a very handy device for alot of things found in most everyday devices- which previously there was no easy way to test them that I know of. Care must be taken to set the dial correctly and not flip the dial after the part is installed otherwise you can expose a part to the wrong test and apply too much power to the part accidently. Keeping a notebook on how to test a part is important so you can repeat that test the same way next time too. The apearance of this tester is deceivingly simple. It is labeled as a transistor tester but it is so much more than that. It not only tests standard transistors but all of the oddball ones too and many more parts. It is very versatile and performs odd-ball tests that my other testers dont do. There are a few tests that a few of my testers have in common.

On some tests the TEST button is pressed and on other tests the TEST button is not pressed. Read the specifics on whether that test requires the TEST button to be pressed. Note that when the TEST button is pressed - the red LED "HV" next to the TEST button - lights up.

Purchased brand New in 2012 year.

Update 12/14/15

I credit this tester in identifying the voltage on a hard to identify Zener diode. It gave me the voltage and reverse voltage - and was able to match the zener type based in its readings. I know of no other tester which could have provided me with this information. It is a great component parameter tester. Its extreme ability to actually generate high voltages and test components at their high voltage specs (in the case of the above mentioned zener diode 160V) is a very welcome feature. I have other testers whichg identify zeners but thopse testers are only for low voltage parts. This one is very capable. See "Zener Diode Test" on this page to see my procedure notes.

Duoyi DY294 Tester Notes

Test 4ea AA internal batteries condition

(no components connected) turn dial to the right "2a(Ic)" The display shows battery volt (4ea AA batteries at 1.5v each should give you 6volts or better - the tester will work with weak batteries on most functions but some functions require peak batteries to give accurate reading) It is not necessary to press any button with this test.

AC Adapter

6V DC 2A using the jack on lower righthand front panel. + is the center connector. When using the ac adapter - make sure internal batteries are removed.

Voltage Regulator Testing

78XX and 79XX etc insert in 321 holes. With 78XX the regulator faces towards me. With 79XX the regulator faces away from me. Move dial to "78xx" or "79xx" and press TEST button and read display volts. Internal 4ea AA batteries need to be strong for accurate results. For example 7806 installed correctly with good batteries installed will show 06.0V when Test buton is pressed. Make sure your parts legs are free of excess solder or it will "booger up" your test holes as it is a tight fit since the legs just barely fit through the holes.

LED Test

Turn dial to "10mA(Ib) NPN (Put long lead of LED in "C" hole. Put short leg of LED in E hole) The led will shine brighter in other dial positions but this lower power position is safest for the LED as you dont want to burn out the LED - just test it. 10mA is enough to light most average LEDs without harm. Over time/decades of use - some LEDs grow dimmer with age. I suggest that dial is turned without anything inserted. LED should be installed AFTER dial is turned so as to avoid higher power ranges which can damage lower power LEDs. Display shows turn-on voltage of LED. Putting LED backwards does nothing and LCD shows only internal battery voltage of 4ea AAs installed. Typical red LED will show 1.76V for example when inserted correctly. No buttons are pressed during this test.

Zener Diode Test

Use E and C holes. Set dial first before inserting part. Set dial to "200V" NPN. Insert zener diode into E and C. Stripe side = C hole which gives Breakdown voltage when you press TEST button. Insert zener diode with stripe side = E which gives Forward Voltage Drop voltage when you press TEST button. Remove part and move dial to ICEO NPN and then insert diode (both ways) press TEST gives ICEO reverse leakage current. Having good fresh AA batteries installed is important for accurate reading

Varistor "Operating Voltage" Test

If the Varistor's value is 300V or below then use 200V NPN setting.

If the Varistor's value is above 300V then use 1000V NPN setting.

(300V is not a misprint and 200V is not a misprint and 1500V is not a misprint)

Turn dial to "200V NPN" or "1000V NPN" depending on your varistors value (see above note) Locate the capacitance test socket located in the lower right hand corner of the tester. Warning - This is a high voltage test - keep your hands away and dont touch any part of the meter or varistor during test. After dial is set and you have inserted varistor into the capacitor test socket - then press TEST button. The display will show the "operating voltage" on the display. It may vary a little from that written on the part. Release TEST button. Set dial to off before removing varistor. Avoid electric shock by not touching any part of the tester or varistor. This test generates up to 1500volts. Be very careful. I know of no other tester which can test a varistors "Operating Voltage".

Varistors and Disc Shaped capacitors look similar - be sure you identify the part correctly. Only run this test for Varistors.

Polarized Electrolytic Capacitor "Withstand Voltage" Test (medium size or smaller barrel shaped caps)

Locate capacitor holes labeled C+ and C-. Move dial to 200V NPN. Insert the legs of the capacitor into the correct socket hole. The stripe side of the capacitor is the minus side. Read the capacitors voltage and write it down. The way the capacitor is inserted - makes the capacitors value as writton the capacitor itself - faces the wrong way - so writing it down helps you remember - not to exceed the voltage that was written on the cap itself. This is a slow test and takes awhile and is a battery hog - will drain your batteries. Press TEST button and keep it held down until your voltage increases to the voltage written on the cap itself. This meter only tests the "withstand voltage" of the cap. It does not test ESR. It does not test capacitance. I know of no other tester which can test a capacitors "withstand voltage". It will even test capacitors which have a couple of hundred volts "withstand voltage" value.

Remember to discharge the capacitor by shorting the capacitors leads together before and after this test to prevent personal injury from a charged capacitor. Dont touch a charged capacitor's leads or partially charged capacitor. A DC 6V 2A power adapter is recommended for this test (plug into DC6V receptacle located just above the capacitor test socket holes. Otherwise fresh batteries are needed for accurate test (remove batteries when using power adapter plug). Test will quickly drain batteries. A bad cap will not charge or the voltage will cease to climb or will stall or will hesistate. A good capacitor will climb steadily but slowly towards the voltage. Once you reach the voltage - then let go of the TEST button. Do not surpass the voltage written on the capacitor. For example - if the capacitor being tested is a 16V6800uF then do not exceed 16v - after it climbs to 16v on the display - be sure to release the TEST button. I dont know what the consequence of not releasing is - possible capacitor rupture or worse or tester damage or capacitor internal damage - unknown. I suggest only testing it properly.

Transistor PNP and NPN (standard types)

ICEO Reverse Leakage Current test

Turn dial to ICEO (either PNP or NPN depending on which type the transistor data sheet indicates). Use a datasheet or by cross-reference to a substitute candidate data - which legs are EBC or BCE. Insert into the correct socket holes in the tester as appropriate BCE or EBC. Press TEST button. The display should read "000" to indicate that the transistor is not leaky. Anything other than "000" denotes leakage and the transistor is faulty. Remove transistor. Turn dial to off.

hFE (gain) test (3 tests gives gain at 3 fractional amps settings) - make sure your transistor can handle this amperes

Turn dial to hFE 10mA (PNP side or NPN side depending on datasheet specification) Use a datasheet or by

cross-reference to a substitute candidate data - which legs are EBC or

BCE. Insert into the correct socket holes in the tester as appropriate

BCE or EBC. There is no need to press TEST button. hFE (gain) is shown on display. Compare to datasheet.

Turn dial to hFE 1mA (PNP side or NPN side depending on datasheet specification) Use a datasheet or by

cross-reference to a substitute candidate data - which legs are EBC or

BCE. Insert into the correct socket holes in the tester as appropriate

BCE or EBC. There is no need to press TEST button. hFE (gain) is shown on display. Compare to Datasheet.

Turn dial to hFE 10uA (PNP side or NPN side depending on datasheet specification) Use a datasheet or by cross-reference to a substitute candidate data - which legs are EBC or BCE. Insert into the correct socket holes in the tester as appropriate BCE or EBC. There is no need to press TEST button. hFE (gain) is shown on display. Compare to datasheet.

Example C2166 shows "023" which is a HFE gain of 23 at 10uA in socket BCE.

VCE(sat) Collector to Emitter Saturation Voltage (2 tests at 800ma and 2A - not all transistors can handle this amperes)

Turn dial to 800mA(Ic) (PNP side or NPN side depending on datasheet specification) Use a datasheet or by

cross-reference to a substitute candidate data - which legs are EBC or

BCE. Insert into the correct socket holes in the tester as appropriate

BCE or EBC. There is no need to press TEST button. VCE(sat) is shown on display. Compare to Datasheet. (be sure your data sheet shows it can handle this 800mA before testing) Batteries must be fresh for accurate results (otherwise remove batteries and use Ac adapter 6VDC 3A)

Turn dial to 2A(Ic) (PNP side or NPN side depending on datasheet specification) Use a datasheet or by cross-reference to a substitute candidate data - which legs are EBC or BCE. Insert into the correct socket holes in the tester as appropriate BCE or EBC. There is no need to press TEST button. VCE(sat) is shown on display. Compare to Datasheet. (be sure your data sheet shows it can handle this 2A before testing) Batteries must be fresh for accurate results (otherwise remove batteries and use Ac adapter 6VDC 3A)

Diode (standard types) Reverse Breakdown Voltage

Turn dial to ICEO(2000uA) Insert diode into E and C (either PNP or NPN side of dial will work but - or + on display may be opposite) For example on 1N4003 diode turn dial to npn side ICEO(2000uA) stripe of diode goes into C hole. Non-stripe goes into E hole of test socket. Press TEST button. Display shows "000" leakage. Remove diode and reinsert opposite (stripe goes into E hole and non-stripe side goes into C holeof socket) Press TEST button shows "1252" Reverse Breakdown Voltage (weak batteries 5v) Remove diode and turn dial to off.

Dual Fast Recovery Power Rectifier

Turn dial to ICEO(2000uA) NPN side of dial. Insert middle leg into E of large socket. Touch side let to C raised metal contact. Press TEST button. Read display. Release Test button. Rotate Rectifier keeping the middle leg in E hole. Rotal so the other outside leg touches C raised metal contact. Press TEST button. Read display. Remove Dual Fast Recovery Power Rectifier. Turn dial to off.

(Note turning the rectifier such that the middle pin touches C raised metal contact and the outside pin (1 test for each outside pin) goes into E hole. Press TEST button gives "000" display. Remove Rectifier. Turn dial off.

Example MOSPEC F12C20C gives "000" leakage result and "1257" and "1257" reverse breakdown voltage result (weak batteries 5v)

Transistor Parameter Testing Note

Basic Functional Testing transistors can be accomplished by Gain (HFE_ and Leakage for most transistors and it will catch most issues. This next section is about advanced transistor testing "parameter" testing.

The parameters of a given transistor can be determined by inserting the BCE legs of the transistor into non-matching BCE combinations of the socket (BEC, CEB, EBC, ECB, etc many combinations). This produces a wide variety of test results according the the mismatching of leg to socket hole mis-combinations. This "mismatching is not arbitrary and it is not done willly-nilly or random. Follow the below instructions step by step in order to see the transistor "parameters" (I will document this later - to be continued)

odd transistor types

FET

SCR

Triac

high voltage non-polarized disc capacitors

AC filter capacitors

Too many to list (this is a work in progress)

HP 990B SMD tester

is a Resistance / Small Voltage / Standard Diode & Zener Diode /small battery / Capacitance (not ESR) tester which has built-in tweezer probes (and included add-on handheld probes). I use this occasionally when I work on surface mount boards with very tiny soldered-in components. The best feature about this tester is its ability to identify Zener diodes voltage rating value (not as accurate as my other tester but good enough to determine if a component is blown). Another unique feature is with the push of a button the tweezer tip polarity changes opposite which makes testing standard diodes simpler as the buttonpress allows testing a diode in both directions easily.

For example when testing a brand new in the package 4.7v Zener diode this tester will give a value of 4.01V and .063 reverse. Good enough for testing purposes - to determine if a zener is good/blown.

It has the functionality of a VOM multimeter with some additional features ( for example like zener test ) - however it is only for small voltage sensitive rating parts - not for use on big voltages or powerful components. Runs on 2 AAA batteries Purchased Band New in 2012 year approx.

Update 12/15/14

I suggest removing the batteries immediately after use. My first unit worked just fine for 1 day and one day later was found dead on a few but not all functions - and exchanged by a kind China vendor. I can only suspect the internal batteries caused some issue. I have had nothing but good service from my second unit, and I always take out the batteries. There is no on/off switch.

This is a very old tester and works very well. I trust it to give me the correct display of Voltage AC or DC or Ohms or Amps or Diode Test or Continuity Beep. It is easy to use due to its autoranging and autopolarity. It runs off one 9volt battery which lasts for more than a year of my use. I own several multimeters or VOM meters but this one gets used the most and I keep it handy to test batteries and electronic components etc.

My Fluke 73 is dead-on accurate.

For example I noticed a year ago that my AC power was higher than it was supposed to be. I initially caught that over-voltage when I tested the outlet with a Killawatt meter (also very good) and then I doublechecked the voltage on my Fluke 73 - same reading. When I called the electric power company to report 126.5V AC from my outlets the lineman that arrived confirmed this fact and said that he also measured 126.5v AC and he said that it is high but still within electric company guidelines - no repair done to the line. (Illinois USA AC varies nowadays from 123 V AC to 126.5 V AC and it is a bad idea to plug in older appliances and electronic gear without stepping down the voltage to within range of what the device requires.)

The Fluke 73 is a professional tester and is trusted by many millions of technicians.

|

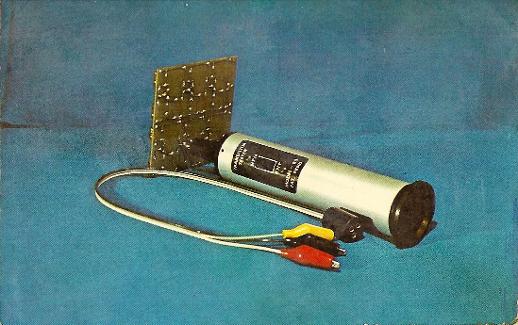

AD1440002 Post Card Side1.jpg Size : 359.495 Kb Type : jpg |

It doesnt test all transistors but tests enough that it is a help when checking for transistors that are bad - without desoldering the transistor. It has a brushed metal round case that resembles a microphone. The back cap is a press-fit and inside is the tiny headphone-like speaker and the speaker is moved outside the case dangling to replace the battery. The plastic cap on mine is original but doesnt hold itself in place- the previou owner used a piece of electric tape for a press fit which was unbelieveably very very very tight. I used a piece of celophane tape as a spacer for now. A set screw would be a better way to do this.

It runs on 1ea 9V standard rectangle battery and I always take out the battery because there is no power switch.

|

Production Devices instructions Mod 85.txt Size : 1.003 Kb Type : txt |

|

Production Devices Mod 85 w instructions.JPG Size : 143.481 Kb Type : JPG |

|

Production Devices artcle IC tester Page 1.JPG Size : 60.407 Kb Type : JPG |

|

Production Devices IC Tester Article Page 2.bmp Size : 1624.9 Kb Type : bmp |

It doesnt test all transistors but tests enough that it is a help when checking for transistors that are bad - without desoldering the transistor. Battery is accessed by unscrewing 2 screws and separating the case halves.

It runs on 1ea 9V standard rectangle battery and I always take out the battery because there is no power switch.

|

3ea Transistor Testers model 100.JPG Size : 75.384 Kb Type : JPG |

|

Production Devices instructions Mod 100.txt Size : 1.666 Kb Type : txt |

This tester works very well to locate dead or shorted transistors in circuit. It is a 2-handed IC tester. One hand is holding the body of the tester and pointing the sharp green probe and touching it to the BASE of the transistor (usually the middle leg but not always) and the other hand is holding the red/white probe and touching it on the EMITTER and COLLECTOR of the transistor. One feature I really like is that the internals of this tester are alternating back and forth between Base and collector - so it is not important to know which one is which while testing. The result is a blinking LED if the lowpower transistor is good. The blinking LED is due to the internals switching back and forth between collector and emitter on the red/white probe. This feature is a big time saver. I'm going to call this feature self-permutating as it hunts on its own for Emitter and Collector on the red/white probe.

Quickly scanning transistors is easy and can be tested in just a few seconds each. If the transistor doesnt flash then adjusting the dial to try and find a setting where a flashing LED is observed or switching the NPN/PNP switch is needed. If the LED flashes then the transistor passes the GO/NO GO test.

The manual shows how to test diodes and power transistors.

Some Words of Caution

The power jack is not for connecting power (runs only on internal 3ea AA batteries). The power leads which are colored with a black wire and red wire are not power leads at all. Never connect any power to the power leads. The red and black wires (and alligator connector) and power jack is for testing power tansistors. The red and black wires are not needed for testing small signal transistors. There is another typo in the manual - the lightbulb does not light up during self test - only the LED. The lightbulb lights flashes when testing power transistors and pass. Probe leads are very sharp and hazardous - CAUTION

It runs on 3ea AA batteries and I always take out the batteries because there is no power switch. Also The probe tips are very very sharp and hazardous. This tester was made in the 1960s and I was lucky to find in pristine condition in 2014.

|

AVO TT169.pdf Size : 1510.668 Kb Type : pdf |

|

TT169 Schematic.pdf Size : 585.949 Kb Type : pdf |

I use the above pictured IGBT & Mosfet tester when I test the high power IGBTs. It has three leads and alligator clips. The LED lights or doesnt light to show correct or incorrect operation of the IGBT when the red button is pushed. It is a nice easy way to functionally test these parts. Some IGBTs fail catastrophically (melted/burned etc) on devices --to-be repaired- but others fail and there is no outward sign that the part is internally bad. The click sound and the red light means it is a good part. I have run into bad parts - and the tester either stays lit or stays off or doesnt respond to the button press- which means the IGBT under test is bad. It can also functionally test Mosfets. Runs on 1ea 9V battery. Purchased Brand New in 2011 year.

Consolidated Electronics Inc Semiconductor Tester model PST-5000 and

Seacor Semiconductor Tester model PST-2000 (pictured above)

(also written as PST5000 or Semi Conductor Analyzer. Also sometimes the company was written Consolidated Electric and their website was Con-elec dot com and I see it is down as of recently and their 800 phone number doesnt work and says "disconnected or no longer in service" as of 8/14)

I have recently (Aug 2014/ March 2015) purchased these used testers in fixer upper condition (disassembled and missing parts) Both are nearly complete with minor things missing such as 2ea power adapters and 1ea rear panel and 1ea battery pack. I have reassembled them and have plans to create a homemade power pack and ac charger as close to original as I can fabricate in my shop. I have enough parts between the two units to fully restore both by comparison.

Consolidated Electronics PST-5000 and Seacor PST-2000 are "sister" units - they bear a diferent namebrand but truly are alike in many ways.

The best feature is in-circuit testing of transistors, diodes, scr, triac, mosfets, and many other parts. For some tests the leads can be attached to the semiconductor in any order - it will self permutate the test leads and display the pinout and identify the attached part. The display shows a text description and pinout. At powerup it performs a self test for 30seconds. The testing is performed by holding down the test button for approx 30 seconds after which the test results are displayed. There are 2 tests available Primary Test and High Voltage Test (a third onboard function is voltmeter). It must pass both tests for the part to be "good"

I look forward to the completion of the homemade battery pack - 2ea internal 12v DC packs (10ea x AA Nicad) as this will allow 4-8 hours testing time. The high voltage test puts the packs in series (24V). The Primary Test uses the battery packs in parallel (12V). Pressing the High Voltage test climbs the voltage supplied to the part being tested until it fails or passes (nonharmful to the part being tested - low current and autosenses any changes in the part). The PST-2000 has an upper limit of 2000V and the PST-5000 has an upper limit of 5000V. I dont foresee ever using the maximum high voltage capabilties as capacitors/other parts I test are no-where near that high voltage. Even so it is a very capable tester and easy to use for my low power/mid power component testing.

In many ways it is as easy to use as the "caseless semiconductor testers" that are popular as of this writing for less than $25 on big-auction-site (I have one too see elsewhere on this page - that one only works for out-of-circuit desoldered part testing). These PST testers perform high voltage tests and out-of-circuit and In-circuit tests - that is a drastic advantage over the inexpensive testers. The in-circuit testing capabilties are super great and IS THE reason I bought these. Well worth the effort and expense/cost to purchase and fix these 2ea formerly abused units received in disrepair.

Unknown mfg date and age - I estimate these were manufactured in the early 2000s and probably new costed more than I could afford.

I have tested both units with a makeshift power supply and both power up equally well and seem to be fully functional. My repair notes and photos are listed here.

Update 6/22/15

I went ahead and ordered some parts and pieces in order to complete my units. I ordered 2ea NiMH 12V 1800mAh battery packs, ABS 3/32" (.093") textured sheet total cost approx $27 so far. I plan on cutting the ABS sheet to size to make a back panel - I will use a China 40W laser engraver to cut it cleanly. The 2ea NiMH battery packs are 2x5 arrangement of AA cells. I will snip off the connector (Tamiya RC style) and solder connect the original connecrtor and then heatshrink insulation over the solder joint. Battery packs from China take awhile to arrive and was a good deal at approx $10 each. I will order replacement battery packs for the second unit at a later date. This will allow me to do some testing on both units to make sure they operate fully and figure out the ac charging plug and voltage/amps needed.

(847) 454-7858 between 11am and 7pm daily

drviragopete@att.net

Dr Virago Pete

I received 2ea 12V 1800mAh NiMH battery packs from China yesterday and have installed these in my PST-2000 battery pack assembly to replace the 2ea severely corroded NiCAD packs 12V 650mAh. The main thing was to remove the 4ea rivets securing the aluminum retainer which holds the batterys in place. I used a Dremel tool with a cutoff wheel to grind down the rivets backside (the aluminm side) and then when the rivet was flush with the aluminum - I just grabbed he rivet with a vise-grip and pulled the rivets out. I used 4ea 6-32 philips head screws and 4ea 6-32 nuts to secure the aluminum retaner using the very same holes which were previously riveted. THe screws allow removal of the aluminum plate for future battery pack replacement. SInce the rivets were placed so close to the bend- I had to modify all 4ea nuts to be very flat on one side- that way the nut sits right next to the aluminum bend. If I didnt grind the nut - then I wouldnt be able to fit it using the same holes. This is a nice elegant solution. I used a vise-grip to hold the nut while I useed a Dremel tool to grind it on one side. I also used some foam leftover from packing materials which hap[pened to be the right kind of foam. THe original foam had all kinds of dried gunk from leaking batteries. I put new foam inbetween the batteries - it is very much like original. The only thing I have left to do is cut the Tamiya style plugs off the new battery packs- and solder on the original plug with wires (scavenged off the corroded Nicad packs) and then heatshrink tube over the solder joint. Im very glad it turned out so well - I was thinking about this for a long time and its nice to be so close to completion. I look forward to using my semiconductor analyzer.

The soldering is done - this was very critical as the polarity of the plugs needs to be correct - otherwise the tester can be ruined by hooking up the 2ea internal battery pack's polarity backwards. I double checked my notes and the red/black marker marks on my board. Heatshrink tubing was put on over the solder joints.

I ended up cutting the end off the Zip Drive 5V ac adapter and soldering it onto a 12V 1Amp ac power adapter wall-type. These ac adapters were purchased second-hand and so were expendable. At this time I have tested both PST-5000 and PST-2000 with the same battery pack charged for a couple of hours. They seem to work the same. I am charging the pack for a few more hours- I still have to figure out how many hours to fully charge. The battery packs as arrived from China had minimal power stored. One was at 11v and one was at 10.5v when they arrived. I tested that minimal power and it wasnt able to boot the PST units - but the backlight did light up with that little charge.

See my zip file containing pictures of this PST2000 battery pack rebuild here.

|

PST2000 Battery Pack Rebuild.zip Size : 4156.592 Kb Type : zip |

Update 6/26/15

Im glad to have gotten pretty far along on the PST-5000 replacement battery pack. My 12"x12"x.090" ABS sheet arrived today and I looked through my inventory of metal and plastic cutoffs and pieces I scavenged off of misc things a long time ago. I saved a scrap piece of aluminum in my inventory for years - I dont know what it came off of originally - probably a scavenged for parts old dot matrix printer. Years ago people threw tons of crt moniutors and dot matrix printers in the trash and I scavenged some for parts and gears and motors and screws and nuts/bolts etc. Thats where this aluminum sheet came from - scavenged by me personally and saved - for someday possibly being useful for something. This sheet of aluminum was a pretty close match for the original thickness. The original PST-2000 battery tray was made form .030" aluminum and my scrap piece of aluminum was .040" thickness. Pretty darn good find and I made a replacement battery tray as close as I could reasonably make it. Im pleased with the end result.

I used a Delta scroll saw to cut out the ABS sheet after measuring the front faceplace (and tracing it) from the PST-5000. I filed the edges with a fine cut file. It is nice and straight and fits well into the PST-5000 case.

I used an unknown make/model of sheetmetal sheer to cut out the scribed lines and magic marker lines which I transferred from my paper template. This sheetmetal sheet cut nice and straight and otherwise I would have to use a bandsaw or nibbler. The sheetmetal sheer is very small and is a table mounted device with a pull-down lever - which has a shearing action. It made easy work of this project. I filed the edges and planished the edges which curled a little bit - I planished it down using a modified sawblade retoother (unknown brand or model) which I made a new die for (a long time ago) and it straightens sheetmetal beautifully.

I looked through my punch die set and I didnt have a 3/4" punch as my set of dies only goes up to 1/2". This handheld model punch I modified ( a long time ago) to be table mounted and I added a long lever to make punching sheetmetal effortless. (See my links above if you like these tools and want to make on e of your own - my CDROM plans show you how I modified it) I made the battery tray's center hole much wider than 1/2" punch diameter by nibbling out a larger diameter. The make-shift hole is decent and will easily fit the battery connectors through this hole.

I used a vintage DI-Acro finger brake press to make my bends - I did my best to compensate for the thicker metal than original. It is a slightly wider and longer and taller than the original - this is so the battery will still fit in there and not an interference fit. I made my paper template slightly larger in all directions than the original PST-2000 aluminum battery tray.

The holes where the mounting screws go - I cannot punch those because it is too close to the bend. I didnt want a sloppy bend - the holes can affect the bend quality. I will manually drill out those four holes later.

Also yesterday, I was charging up my completed PST-2000 battery pack and I tried it in both PST-2000 and PST-5000 and worked fine - the 4 hour charge was excessive because I listened to the battery pack (at 4 hours of charging) and it was fizzing like a glass of soda. This tells me that the 12V DC 1Amp wall adapter I used was WAY too much amperage. Based on my battery capacity of 2ea 12V DC 1800mAh internal - I estimate the 12V DC power adapter ideally should be around 200mA or less - which would take 5X as long to charge - but it would heat up the battery substantially less. I need to find a 12V DC power adapter because if I continue to brute force this battery pack - the battery capacity will be diminished or the PST unit will be harmed. It just was WAY too much amperage for charging - it doesnt seem like there is internal regulation of charging amperage or current limiting. The solution is just to use a lower capacity 12v wall adapter next time.

|

PST-5000 Replacement Battery Pack Build Part A.zip Size : 4807.5 Kb Type : zip |

I made a test fit of the aluminum battery tray onto the back of the installed blank ABS rear panel - before any drilling and used magic marker/6" dial caliper to see where the holes should be. I used a center punch to make sure the drill bit didnt wander. Then I drilled only the aluminum battery tray 4ea holes.

I drilled the 4ea holes in the plastic one at a time - using the drilled battery tray to keep the drill bit on targetwhile going through the plastic panel - installing the first nut/screw and then drilling the next one and installing that nut/screw - to keep it in perfect alignment - so none of the holes are crooked or misaligned. Also I used a tapered deburring tool after the drilling to make sure the holes are neat and free of jagged edges.

It turned out pretty well - and if I didnt tell you - you would think it was made that way from the factory. I stacked the PST-5000 and PST-2000 for a side-by-side comparison. I saw a photo of a PST-5000 which was for sale on big-auction-site and was just too expensive - but that one showed a rear photo of the PST-5000 - and I used that saved photo to make my replacement rear panel similarly - I noticed the screws are farther apart - from my own PST-2000 original tray - so on my PST-5000 batrtery tray - I also made the screws wider apart. I think the reason is - the power jack is the center on the PST-5000 whereas the power jack is on the left on the PST-2000 (I havent decided where that photo was a modded one or factory stock that way because it had a 4-pin connector on the rear panel ???). I havent decided whether Im going put my own power jack in the center or top left. I still need to purchase the 3ea 3-pin connectors and the power jack and the 12V 100mA to 200mA AC adapter and also 2ea NiMH battery packs. So I have a ways to go in small purchases - but the hard part is done - the back panel and aluminum battery tray are built and it looks decent and good - its looks professional - like a factory made it. I did my best.

|

PST-5000 Replacement Battery Pack Build Part B.zip Size : 4836.344 Kb Type : zip |

I received 4 pairs of "Banana PLug to Test Hook Cable Probes" ordered from big-auction-site and came from China. I ordered 4 pairs due to needing 6 total wires for both PST units. Also a spare set was ordered for use with my Lissajous tester. The pair of cables is red/black and I plan on using all red on one unit and all black on another unit. The lissajous tester will get the red/black pair. I paid $1.82 plus $.39 shipping for each set. I pay a whole lot more when I ship something even within the same state of Illinois. It was a remarkably low price. I tested one set of clips on the PST-2000 for about 1/2 hour going through about 30 various transtors and N-channel mosfets etc. I like these clips they work well and allows for hands free holding of the parts. The PST units require the test button to be held down during the test - so grabbers or alligator clips is necessary. Here is a photo of the test leads.

|

Banana Plug Test Hook Grabber.JPG Size : 79.841 Kb Type : JPG |

|

Misc Pics PST-2000 and PST-5000.zip Size : 2073.68 Kb Type : zip |

|

consolidated_electric_pst_5000.pdf Size : 152.351 Kb Type : pdf |

|

PST-5000 Brochure.pdf Size : 1080.333 Kb Type : pdf |

|

PST-5000 as received 101714 part A.zip Size : 10535.688 Kb Type : zip |

|

PST-5000 as received 101714 part B.zip Size : 9347.491 Kb Type : zip |

|

PST5000 & PST2000 My Repair Notes April 2015.txt Size : 10.49 Kb Type : txt |

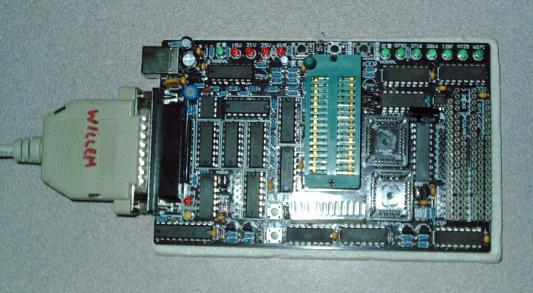

Caseless LC/ESR Component Tester PCB Booster Edition ver 2.2 firmware 1.02K

Purchased from big-auction-site approx end of 2012 for about $20 from China. It is a very common tester with some good features. It doesnt do in-circuit testing or thorough transistor testing. Leakage testing - it doesnt do that either. It does quick component identification including pinous of the lead order BCE EBC ... it does that very well. Even so I just dont find the information that it gives to be useful. When I check a component I compare the book specifcations to the readings of the transistor. I find that measuring leakage of a transistor is very important and this tester doesnt do that. Some newer style big-auction-site testers do measure leakage. But I have been using my BK815 for years and a cheap little tester is no comparison to a profesional arsenal of testers. Even though this less than $20 tester is well worth the money paid. It sits in a small box very little used.

I decided to post my knowledge on backlight for this 1602 LCD display. The tester is a battery hog and NOT HAVING a backlight makes your battery last a whole lot longer. But this simple LED mod which basically costs nothing - every electronics hobbyist has an LED to spare.

The short end of the LED goes on the very end of the single-inline-connector (see pics). The longer LED lead goes on the second to last hole of the single-inline-connector. This demonstrates a 1602 backlight or non-backlight version and which pins (the last 2) are for the backlight. For non-backlight LCD - these 2 pins are missing. A simple backlight is putting a standard LED on the side of the LCD module held in place with a dab of epoxy or silicone caulk. Thats my "CHEAP Backlight Mod" for your Cheap $20 component tester. Otherwise just use a 1602 backlighht edition LCD module and plug it in. It will work just fine but the battery will drain quicker.